Steel Grating Sizes: Understanding Grate Variations and Specifications

Steel grating is a multifunctional and essential component across various industries and buildings. It doesn't matter whether you are working on walkways, platforms, or drainage covers; knowledge of steel grating sizes, types, and specifications will help you maintain both functionality and safety. This article will highlight the main differences between steel grating and explain the factors that affect its design, load capacity, and performance. You will, therefore, know exactly how to choose the right steel grating for your particular requirements by the end of this article. Find more info now.

Types of Steel Grating

Steel grating can be divided into three primary categories according to their construction and application:

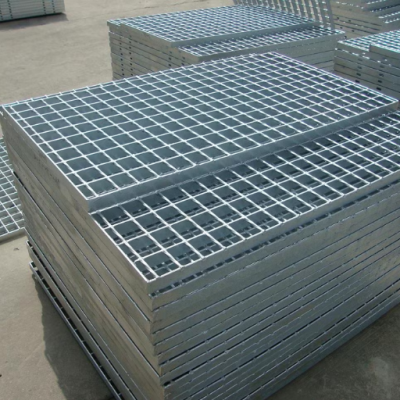

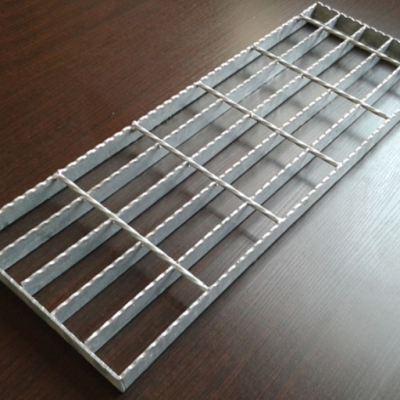

Welded Steel Grating

In this case, the bars are the main structural components, welded at their intersections to form a sturdy, long-lasting grid frame. Its main areas of usage are platforms, walkways, and industrial flooring due to its strength and excellent load-bearing capacity.

Press-Locked Steel Grating

Press-locking produces a smooth surface that is ideal in architectural or similar where aesthetics are a priority. Press-locked grating is created by inserting and fusing crossbars into the bearing bars.

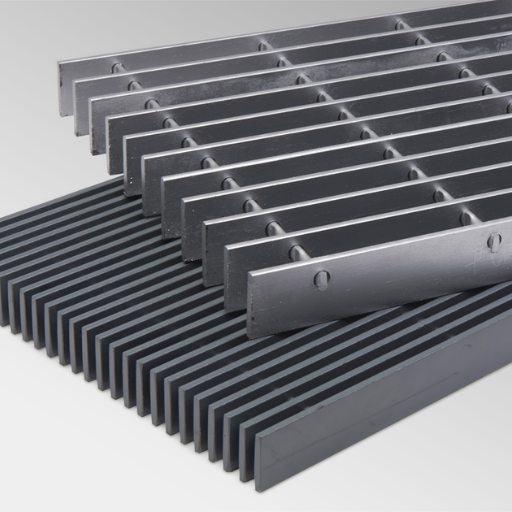

Swage-Locked Steel Grating

The swage-locked grating is made by swaging the crossbars into the pre-punched holes in the bearing bars. This construction provides a strong yet lightweight structure, ideal for pedestrian areas and applications requiring quick installation.

Ultimately, each type serves a different purpose thus it is vital to identify and select the right type distinguished by the key factors; the structure demands, aesthetics, and functionalities.

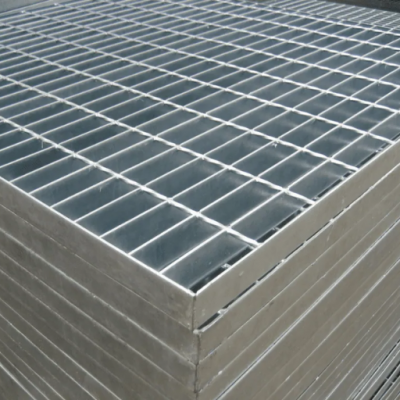

Overview of Steel Bar Grating

Steel bar grating is a durable, cost-effective option for various industrial and commercial applications, offering strength, safety, and cost-effectiveness. The product is generated by welding or locking together a number of parallel bearing bars, which create an open grid structure. This specific arrangement not only enables the bearing of heavy loads but also allows proper airflow and drainage, making it suitable for applications such as catwalks, platforms, and drainage covers.

Key Benefits and Applications

High Strength-to-Weight Ratio

Steel bar grating is designed to withstand the heaviest loads while remaining light. This property makes it suitable for a variety of applications, including bridge decking, factory floors, and building skins. It comes in different types and sizes, and depending on the type and size, it can support loads from light pedestrian traffic to heavy machines.

Corrosion Resistance Options

Galvanized or stainless steel grating is corrosion and weather-resistant, making it perfect for outdoor use and extremely harsh conditions. For instance, a hot-dip galvanizing method can protect steel for up to 50 years in a non-coastal, non-industrial environment, thereby significantly reducing maintenance costs.

Wide Range of Types and Sizes

Steel bar grating comes in a variety of types, like welded, press-locked, and swage-locked. They are available in several thicknesses, spacings, and lengths. For example, the height of the bearing bars is usually between 1" and 4", while the spacing between the bars is commonly between 3/16" and 1-3/16".

Safety Features

Serrated steel grating provides a slip-resistant surface, thereby minimizing the risk of accidents in high-traffic areas. Furthermore, it is fire-retardant, thereby enhancing its safety in application.

Latest Industry Trends and Data

Projected Growth

Recent reports suggest that the global steel grating market will expand at a CAGR of about 4-5% during 2023-2030, primarily driven by rising demand from infrastructure development projects and industrial facilities.

Material Preferences

Among the materials, stainless steel is the most in demand because of its strength, resistance to rust and corrosion, and the need for no periodic maintenance. Its presence is felt across the oil and gas, chemical processing, and food industries.

Innovative Solutions

To make the steel gratings appealing and functional, manufacturers are employing advanced coating methods such as anti-slip paint and powder coating.

During the selection of steel bar grating for your project, it is very crucial to determine the specific requirements such as load capacity, environmental factors, and safety aspects. This way, an optimal design solution can be ensured.

Standard Duty vs. Heavy Duty Grating

Key Point | Standard Duty Grating | Heavy Duty Grating |

|---|---|---|

Material Thickness | Thinner bars | Thicker bars |

Bar Spacing | Closer spacing | Wider spacing |

Load Capacity | Suitable for lighter loads | Handles heavy loads |

Applications | Pedestrian areas, light traffic | Industrial, heavy machinery, vehicles |

Slip Resistance | High due to closer spacing | Moderate, larger openings |

Cost | More economical | Higher upfront cost |

Maintenance | Easier to clean | Requires frequent cleaning |

Durability | Moderate durability | High durability |

Weight | Lightweight | Heavier |

Safety | Better for slip prevention | Caution needed in slippery areas |

Common Types of Metal Grating

Metal grating is divided into categories based on its design, the materials used, and its application. Below are the most common types of metal grating along with descriptions to help people in selecting the most suitable one for their special usage:

Welded Steel Grating

Welded steel grating is the most widely preferred type due to its hardness and long life. It consists of steel bars joined by high-pressure resistance welding, forming a strong, consistent structure. Major uses are in the configuration of industrial flooring, walkways, and platforms. This category is highly recommended for places that require heavy load-bearing capabilities and is available in different bar sizes and thicknesses. It is usually found in factories, storage areas, and oil refineries.

Press-Locked Grating

Press-locked grating is the perfect combination of beauty and utility. The creation involves pressing and locking cross bars into bearing bars under high pressure. This kind offers a high degree of personalization, with an array of styles and spacing options that make it suitable for architectural applications such as sunshades, building facades, and decorative elements. However, it is not very suitable for very high-load areas but it does provide better visual appeal.

Swage-Locked Aluminum Grating

Swage-locked aluminum grating is lightweight but strong enough to withstand the rigors of the application. The manufacturing process involves the permanent interlocking of cross bars with bearing bars to provide stability. It has high resistance to corrosive environments, for example, in the marine and chemical industries, and is widely used in maintenance platforms, shipbuilding, and waste treatment plants.

Expanded Metal Grating

Metal grating made by expanding the sheet is a diamond-shaped mesh pattern formed by cutting and stretching the sheet. The lightest option not only is cost-effective but also improves slip resistance, which is the reason for its wide application in walkways, fencing, and ventilation covers. It is suitable for areas with moderate load-bearing capacity, and safety is prioritized.

Fiberglass Reinforced Plastic (FRP) Grating

FRP grating is not metallic, however, it should still be mentioned as it is gaining popularity. It is made using a combination of resin and fiberglass, which gives it superior corrosion resistance, non-conductivity and lightweight. The primary uses of FRP are in highly corrosive environments like wastewater treatment plants, food processing plants, and chemical plants.

Data Insights for Metal Grating Selection

Load Capacity: Steel bar grating can accommodate loads of the same order as heavy-duty applications up to 7,000 pounds per square foot, hence making it the favored option in industrial environments. For lighter applications, however, aluminum or FRP grating with a load capacity of about 1,500 pounds per square foot is often adequate.

Corrosion Resistance: According to industry data, aluminum and FRP grating have about 50% longer service life than traditional steel in corrosive environments.

Slip Resistance: Recent industrial safety studies reveal that expanded metal and specialized anti-slip coatings can enhance safety in dangerous areas by reducing slip accidents by as much as 30%.

Among the many factors to consider when selecting the right type of metal grating —load-bearing requirements, environmental conditions, aesthetics, and safety needs —evaluate them all using the "performance and longevity" criterion to achieve optimal results.

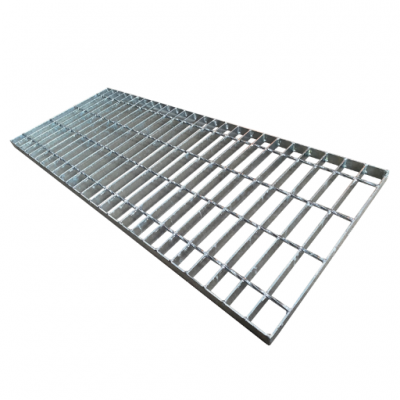

Size Specifications for Steel Grating

Steel grating is available in many sizes to accommodate the varied requirements of various applications. The size specifications are normally classified by the spacing between the bars, and the widths and lengths of the panels. The following are the standard specifications for steel grating:

Bearing Bar Spacing: The distance between the centers of the adjacent bearing bars can vary depending on the application. The most common spacings are 30mm, 40mm, or 60mm, with 30mm typically used in railway or similar industrial areas that require a strong, closely spaced grating.

Cross Bar Spacing: Cross bars are the ones providing lateral support and usually have among the 50mm or 100mm spacings depending on the load-bearing requirements and design preferences.

Panel Dimensions: The dimensions of the standard steel grating panels typically vary in widths from 600mm to 1000mm and lengths can be as much as 6000mm. The custom sizes can be made for specific applications.

Thickness and Bearing Bar Height: The bars are usually a thickness of between 3mm and 10mm, and their height can be anywhere between 20mm and 100mm depending on the load that is going to be applied to them.

Load-Bearing Capacity: Steel grating can be used for a wide range of loads, from pedestrian traffic to machinery. An example would be a grating with 30mm bearing bar spacing and 5mm bar thickness, which is capable of handling light vehicle loads, while higher specifications might be needed for heavy industrial use.

Weight per Square Meter: The weight of steel grating usually falls in the range of 20kg/m² to over 40kg/m² depending on the size and type. This can be a factor in the installation style and the structure's requirements.

In the process of selecting the right steel grating sizes, one has to consider many factors like the maximum load that it should support, the environmental conditions under which it will be used, and the type and volume of traffice expected. Manufacturer's data or standards, such as ANSI/NAAMM standards, can provide extra technical information for specific projects.

Understanding Bar Grating Sizes

Bar grating sizes are majorly grouped in accordance with the distance between the bearing bars along with the cross rods, total thickness, and type of material. The mentioned dimensions are critical in evaluating the grating application area, strength, and life span. Some key points and typical configurations are provided below:

Standard Spacing:

19-W-4 (19/16" spacing, 4" cross-rod centers): This is one of the most widely used configurations, providing a good balance of strength and opening area. It is used in the industrial sector for platforms, walkways, and mezzanines.

15-W-4 (15/16" spacing, 4" cross rod centers): This one has the bar spacing tighter which results in higher load-bearing capacity and less open area. Heavy-duty applications, such as heavy-duty forklift traffic, are suitable areas for it.

Heavy-Duty Grating:

Heavy-duty bar grating is designed for the most demanding environments where extra strength is required. These types of gratings usually consist of thicker bearing bars (up to 3/8” or more) and wider spacing like 30-W-4 or 60-W-4 options. They are perfect for areas with heavy vehicular traffic, such as highways, bridges, and airport runways.

Materials:

Carbon Steel: This grade is the most common and cheapest, and carbon steel gratings can be often found in places where rust resistance is not the main issue.

Stainless Steel: This type is most used in the harshest conditions like wastewater treatment, food processing, and chemical manufacturing plants.

Aluminum Grating: This grate is lightweight and corrosion-resistant, making it ideal for use in environments such as rooftop walkways or offshore platforms.

Specialized Patterns:

Close Mesh Grating: A type of grating with small openings that is ADA (Americans with Disabilities Act) compliant in terms of resistance to slipping and small items falling through.

Custom Gratings: Many suppliers provide the possibility of adjusted solutions for unique projects, including with different bar thicknesses or custom-cut shapes.

Load and Deflection Data:

Load tables from the manufacturer can serve as a guide when choosing the size of the grating. For instance, 19-W-4 grating length with 1” x 3/16” bearing bars can support a load of 5,000 lbs per square foot with hardly any deflection when placed in the right manner. The calculations for the load capacity can be made precise by referring to the ANSI/NAAMM MBG 531-09 standards.

Selecting the Right Size for Your Project

When selecting the right bar grating size, consider the load it will support, the risk of corrosion in the environment, and local building codes or industry standards. It would be advisable to consult reputable manufacturers and use online tools or calculators provided by leading grating suppliers to narrow your choice.

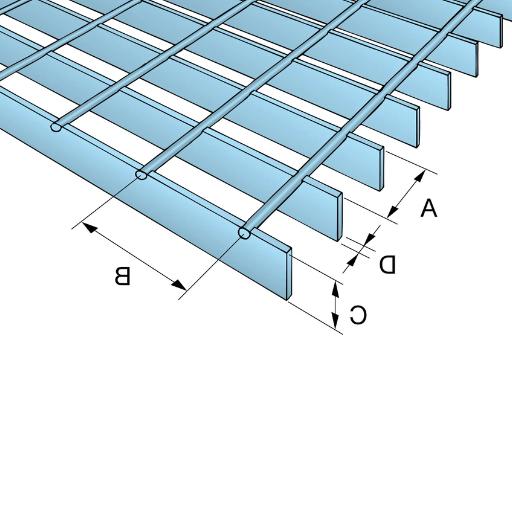

Bearing Bar and Panel Dimensions

When it comes to bearing bars and panels selection, accurate measurements are necessary to secure the building's strength and to have the best performance. Here are five important measurements to think about:

Bearing Bar Depth

The depth of the bearing bar, which is measured vertically and usually ranges from ¾ inch to 5 inches, directly influences the grating's loading capacity.

Bearing Bar Thickness

Thickness varies between light-duty and heavy-duty applications and ranges from 1/8 inch to 1/4 inch.

Panel Width

The first criterion in panel choice is width; panels are available in different widths, with the most common standard width being 24 inches.

Panel Length

The standard range for panel lengths is 20 to 240 inches, determined by the application and material requirements.

Spacing of Cross Bars

Cross bar spacing varies according to distinct load and aesthetic requirements, with the most common spacings being 4 inches or 6 inches on center.

If you set these dimensions correctly to meet the project's needs, you will surely experience the benefits of bar grating in your application through performance and durability.

Standard Grating Panels: 19-w-4 and 11-w-4

Standard grating panels of the types 19-w-4 and 11-w-4 are all very common in industrial and structural applications because of their characteristics such as exceptional strength, uniform appearance, and versatile design. These two panel types represent the specific configurations of bearing bars and spacing designed for different load and functional requirements.

19-w-4 Panel Specifications:

Bearing Bar Spacing - 1 3/16 inches on center

Cross Bar Spacing - 4 inches on center

Weight - About 19 pounds per square foot (varying with the material)

Material - Generally, it is offered in carbon steel, stainless steel, and aluminum

Applications:

Heavy-duty walkways and flooring in power plants and manufacturing facilities

Areas that require drainage and ventilation, like wastewater treatment plants

Being tough and having a large load-bearing capacity, it is also suitable for high-traffic zones.

11-w-4 Panel Specifications:

Bearing Bar Spacing - 11/16 inches on center

Cross Bar Spacing - 4 inches on center

Weight - around 11 pounds per square foot (material used) usually lighter than 19-w-4 panels

Material - Steel varieties or aluminum are commonly used for its production

Applications:

A good choice in pedestrian-friendly areas like public building walkways and mezzanines

Excellent load bearing provided in areas where lighter weight is a plus

Occasionally used in architectural applications, mainly for aesthetic appeal enhancement

Key Comparisons Between 19-w-4 and 11-w-4 Panels:

Feature | 19-w-4 | 11-w-4 |

|---|---|---|

Bearing Bar Spacing | 1 3/16 inches | 11/16 inches |

Cross Bar Spacing | 4 inches | 4 inches |

Weight | Heavier (~19 lbs/ft²) | Lighter (~11 lbs/ft²) |

Primary Usage | Industrial/heavy-duty zones | Pedestrian/aesthetic areas |

Advantages | Superior strength, high load capacity | Lightweight, visually appealing |

Material Considerations:

The, 19-w-4 and 11-w-4 panels, respectively, are both offered in the following materials as listed below:

Carbon Steel: It has a good strength-to-cost ratio.

Stainless Steel: This is the case when the protection against rust is needed and the use of the material in very hostile environments is allowed.

Aluminum: It weighs very little and it is the case that even in places where the saving on weight is very important, its being almost non-corrosive is an advantage.

Using an appropriate panel type for the project, considering load requirements, material preferences, and aesthetic goals, will lead to functional and economical optimization.

Applications of Steel Grating in Various Industries

Steel grating plays a significant role across various industrial sectors due to its longevity, low cost, and versatility. Here are five such applications of steel grating in different industries:

Industrial Flooring

Steel grating is the most commonly used industrial flooring in factories and manufacturing plants. Its strong point and non-slippery surface make it safe for workers and support the heavy machines. For instance, in chemical plants, stainless steel grating is employed for its corrosion resistance, ensuring it lasts in extreme conditions.

Oil and Gas Platforms

Steel grating is frequently utilized for offshore and onshore oil and gas platforms walkways, stair treads, and decking. The grates are very tough and do not easily get damaged. They create proper drainage, provide safety in oil spill areas, and prevent the recurrence of oil spills.

Transportation and Infrastructure

Steel grating is used in bridge decking, drainage covers, and subway ventilation grates. Its flexible design can withstand any load while allowing airflow or water drainage. For instance, aluminum grating is frequently chosen in areas where light, yet strong, materials are required.

Commercial and Public Spaces

Steel grating can be seen in shopping malls, airports, and parks, used for footbridges, stairs, and facades. It is not only a practical choice but also an aesthetic one that is why it is a preferred material in the layout of modern urban designs.

Mining and Power Plants

Steel grating is commonplace in mining grounds and power plants as the material for platforms, ramps, and walkways. Its strength guarantees that it will withstand the heavy-duty demands of power generation and mining applications; meanwhile, stainless-steel alternatives will be resistant to corrosive substances, resulting in longer service lives.

These cases illustrate the multifunctionality of steel grating and the necessity of its use in forming efficient, sustainable industrial and commercial structures.

Industrial Applications of Steel Grating

Steel grating is an excellent material that is utilized across the board in different industries due to its outstanding properties such as durability, strength, and versatility. Below, we present five of the most remarkable industrial applications of steel grating:

Manufacturing Facilities

Steel grating is widely used in the construction of mezzanine floors, work areas, and stair treads, thereby facilitating the flow and processing of activities within factories. It can withstand heavy machinery and is resistant to wear and tear, further enhancing its suitability for harsh industrial conditions.

Wastewater Treatment Plants

Open-mesh steel grating provides drainage and ventilation, making it suitable for walkways and platforms in sewage disposal plants. Its non-slip feature, in addition to being a factor of safety, is a great help for workers operating in environments with moisture.

Oil and Gas Industry

Steel grating is extensively used in offshore and onshore oil exploration and refining platforms and walkways because of its properties of being corrosion-resistant and durable in extreme conditions such as saltwater exposure and high corrosion risk.

Transportation Infrastructure

Steel grating is used in the construction of highway drainage covers, pedestrian bridge walkways, and ventilation grates in tunnels. Its light yet strong structure ensures safety and efficiency in transportation systems.

Power Plants

Steel grating plays a key role in coal-fired and nuclear power plants by supporting heavy equipment and facilitating proper air circulation. Its ability to withstand high temperatures and extreme loads makes it very useful for elevated floors and cooling tower platforms.

Floor Grating Applications

There are numerous uses for floor grating across various industries owing to its long life, strength, and versatility. Here are five major floor grating applications:

Industrial Facilities

Floor grating is a must-have in the industrial facilities for their passenger and emergency exits, as well as their major production areas. It makes the environment safe for workers to carry out their duties thanks to its non-slip feature and good load-handling capability.

Chemical Plants

Wherever floor grating is used in chemical plants, it is always in well-drained, well-ventilated areas, as it provides comfort and stability. The processing of chemicals goes on in places where there is a constant supply of these two important elements and at the same time, the floor is still in good condition.

Oil and Gas Platforms

Floor grating, because of its resistance to corrosion and chemicals, is an important part of the oil and gas industry’s operations. Offshore oil platforms and refineries depend on floor grate to last in tough conditions. It will find its place in places like access stairs, helipads, and safety barriers where strength and resistance to the elements are the key factors.

Public Infrastructure

In cities, floor grating is often very useful for drainage coverage, venting, and even pedestrian bridges. Grating, due to its ability to handle heavy traffic from both people and vehicles, is the material of choice for urban areas since it lasts long in such harsh environments.

Food Processing Plants

Stainless steel is a type of grating suitable for food and beverage processing due to its cleanability and hygiene-enhancing properties. It gives an anti-slip surface, does not absorb water, and allows cleaning easy in the areas where hygiene is of utmost importance.

ADA Compliant Grating Solutions

The grating solutions that are ADA-compliant are made to ensure that access and safety measures for the disabled are taken, and this is done by following the guidelines of the Americans with Disabilities Act (ADA) to the letter. These grates have features that effectively prevent hazards. They also allow for safe and comfortable navigation for everyone. Here are five important attributes of grating systems that conform to ADA requirements:

Maximum Spacing Requirements

ADA-compliant grating allows for no gaps wider than 0.5 inches at any point, which means it is impossible for small wheels like those of a wheelchair to get jammed.

Slip Resistance

The surface of the grating is designed for maximum slip resistance which makes falling less likely and supports safety even during wet or icy weather.

Directional Orientation

Grating bars are placed perpendicular to the main flow of pedestrian traffic allowing for smooth and stable movement with wheelchairs and mobility aids.

Smooth Surface Transitions

The ADA-compliant grating solutions come with smooth, beveled edges that lead to the creation of accessible transitions between different surfaces, thus, reducing tripping hazards.

Load-Bearing Capacity

The grates are constructed in such a way that they can bear a considerable weight load which guarantees that they will last longer and perform well in areas of high traffic, such as sidewalks, ramps, and public paths.

Public and private areas can be made more accessible to everyone by incorporating these design elements into ADA-compliant grating solutions.

Selecting the Right Steel Grating Size

The selection of the appropriate steel grating size is a decision that requires consideration of numerous factors to satisfy safety and functionality needs while also complying with the relevant industry standards. Some leading criteria and help for the proper grating size selection are presented below:

Load Requirements

Based on the application, the load-bearing capacity will be determined. In case of pedestrian areas, the grating should be able to support a while distributed load (UDL) without any problem, whereas, in case of areas with vehicular traffic, grating capable of dealing with even more concentrated loads will be required. For example, heavy-duty grating is usually designed for wheel loads of 5,000 - 10,000 lbs. and sometimes even more.

Bar Spacing

Standard bar spacing occupies an essential place in the triangle of strength, safety, and drainage. Gratings that are compliant with the American with Disabilities Act (ADA) commonly have a maximum opening of 0.5 inches to prevent small wheels from getting stuck and to allow accessibility for people using mobility devices. Heavier applications may use up to 1-inch spacing for more efficient load-bearing.

Material Specifications

The most common types of steel grating are made from carbon steel, stainless steel, or galvanized steel. Among these, galvanized steel offers excellent rust resistance, making it the best choice for outdoor or wet environments. If the project is to have a long-lasting product that is not affected by either environmental or chemical degradation, then, stainless steel is the right option.

Panel Dimensions

Grating panels of standard size have fixed widths, usually 24 to 36 inches, and can be as long as 240 inches; custom dimensions can also be made to suit a specific project. Make sure the panel sizes are compatible with the structural framework, not too difficult to handle during transportation and installation, and within the user's reach.

Application-Specific Needs

The various applications will require different types of grating. For example:

In the industrial areas like plants and factories, a serrated surface can be used for anti-slip purpose.

Drainage grates serving roadways and parking areas are often concerned with the percentage of open area for water to flow freely.

Compliance Standards

Always check if the assigned grating is in accordance with the relevant safety codes and standards that might be either the American National Standards Institute (ANSI) or Occupational Safety and Health Administration (OSHA) guidelines for instance. In the case of ADA compliance, it is essential to ascertain that the grating design incorporates narrow openings and smooth transitions.

Example Data for Steel Grating Selection

Application | Recommended Load Capacity | Bar Spacing | Material | Surface Finish |

|---|---|---|---|---|

Sidewalks & walkways | 100-300 lbs/sq. ft | 0.5 - 0.75 inches | Galvanized steel | Plain or serrated |

Industrial platforms | 500-1,000 lbs/sq. ft | 0.75 - 1 inches | Stainless steel | Serrated |

Vehicular traffic areas | 5,000 - 10,000+ lbs | 1 inch or greater | Carbon steel | Plain |

High-moisture environments | 300-500 lbs/sq. ft | 0.5 - 0.75 inches | Aluminum or stainless | Serrated |

By evaluating these factors and aligning them with project-specific requirements, you can ensure the steel grating selected achieves optimal performance, durability, and safety.

Factors to Consider When Choosing Size

Choosing the right size for steel gratings requires considering many important points that will guarantee the product to be suitable for the application that it is intended for. The following are five major considerations:

Load Requirements

First, determine the maximum weight the grating will support.

For instance, if there is to be only light foot traffic then a capacity of 100-300 lbs/sq. ft might be enough, while in places where vehicles might go it may be better to have a load capacity of 5,000 lbs or more.

Span Length

The length of the beams between which the grating is placed will affect the grating size and thickness to a great extent.

Very short spans (e.g. 2-3 feet) may allow for using thinner grating, while longer spans (5-10 feet) typically require thicker and heavier options.

Bar Thickness and Spacing

The bars’ thickness and spacing are the main factors that determine the strength of the grating and how it distributes the load.

Gratings with close bar spacing are usually the choice for heavy-duty areas, as they provide a longer lifespan.

Environmental Conditions

Consider whether the gratings will be exposed to factors such as humidity, chemicals, or very high or very low temperatures.

Choosing a serrated grating made of aluminum or stainless steel with a thickness of 0.5-0.75 inch is the best option for corrosion resistance in places where there are large amounts of water.

Safety Requirements

In areas with a risk of spills or moisture accumulation, non-slip surfaces, such as serrated finishes, may be required.

Certain applications, like industrial settings, may also require compliance with industry safety standards or guidelines.

By systematically addressing these factors, you can select the optimal size and configuration for your steel grating to ensure safe, efficient, and durable performance.

Understanding Bearing Bar Spacing

Bearing bar spacing is a key parameter in steel grating design and performance. It sets the limit for load-bearing capacity and grating strength, therefore, affecting compliance with safety standards and application demands. The spacing is determined by measuring the distance from the center of one bearing bar to the center of the next one.

Common Bearing Bar Spacing Standards

Industrial Standards:

The standard bearing bar spacing is usually between 19 mm (3/4 inch) and 40 mm (1.5 inches), where 30 mm (1.2 inches) is the most commonly used size for general industrial applications.

The minimum spacing of 19mm is mostly adopted in such cases, where the movement of people or the prevention of small object falling through is of utmost concern.

Pedestrian and ADA Compliance:

The bar spacing is set at 19mm (3/4 inch) for ensuring barrier-free movement of wheelchair users and lack of hazards in area for which ADA compliance is sought.

Heavy-Duty Applications:

Large spacings, 40mm (1.5 inches), may be used when combined with thicker webs to provide the necessary load capacity in very heavy-duty applications such as large trucks or heavy equipment.

Spacing’s Impact on Performance

Load Distribution:

Heavily loaded gratings are usually designed with bars close together to ensure good load distribution and this kind of spacing is especially valuable in situations requiring enhanced safety and stability.

On the other hand, wider spacing would decrease the total weight of the grating, making it more cost-effective but then again, less safe in some environments.

Aesthetic and Functional Considerations:

In architectural application, bearing bar spacing can be tailored to the visual effect while also maintaining structural integrity.

Tight spacing minimizes the escape of waste and/or larger particles, ensuring the area functions well even during littering or contamination.

Durability and Cost:

Tight spacing means that there will be more material used, therefore, the price goes up, but so does the durability.

Wider spacing is cheaper but might not last as long in high-stress areas as the expensive option.

Choosing the Right Spacing

When selecting spacing, night shakily consider these factors:

Load Requirements: Take expected load into account, whether it is pedestrians (lower load) or vehicles (higher load).

Safety Standards: Ensure that local regulations, such as ADA or OSHA, are not violated.

Place: Determine the level of moisture, exposure to corrosive substances and accumulation caused by debris.

By thoroughly assessing application-specific requirements and referring to the latest industry standards, one can determine the most suitable bearing bar spacing for steel grating installation.

Recent Trends in Steel Grating Manufacturing

The steel grating production sector is undergoing rapid change and growth, driven by new technologies, demand for eco-friendly materials, and evolving safety regulations. One of the most important trends is the use of automatic and robotic machines in the making of grates, which have exceptionally improved the accuracy and productivity of the output. For example, automated welding is a fairly common technique nowadays for achieving the best weld joints while reducing production time.

Besides, the industry's focus has begun to shift toward green, sustainable alternatives for color grading. Manufacturers are increasingly using recycled steel in their production, thereby positively affecting the environment while preserving the material's good qualities. An industry report for the current year estimates that the global recycled steel market will increase steadily at a compound annual growth rate (CAGR) of nearly 6% from 2023 to 2030, signaling a clear movement towards sustainability.

Also, the use of lightweight steel grating products is on the rise, particularly in transportation and aerospace, where these products can provide high tensile strength while reducing the overall weight of installations, making operations more efficient. Recently, for instance, they made it possible to develop hybrid grating materials that intersperse steel with composite elements, thereby offering improved corrosion resistance and longer service life in very aggressive environments.

There is increasing demand for more customization in steel grating designs. Producers can provide customized solutions that meet specific architectural and industrial requirements, ensuring the product has both functional performance and aesthetic appeal. This tendency aligns with the growing use of steel grating in urban infrastructure projects, where design flexibility is considered crucial.

All things considered, the steel grating industry is undergoing a rapid transition, and manufacturers are turning to innovation to meet modern requirements for performance, sustainability, and aesthetics. These developments are influencing how steel grating solutions are conceived, manufactured, and deployed across different industries worldwide.

Innovations in Steel Grating Fabrication

New developments in the fabrication of steel grating are going to set new standards for efficiency, sustainability, and performance. The use of modern technologies such as welding robots and laser cutting is allowing grating manufacturers to provide grating solutions of unprecedented precision and uniformity. Just to give an example, automated welding is one of the processes that helps in maintaining the same level of quality throughout the production while at the same time cutting down the production time drastically which results in more economical manufacturing processes.

Sustainability is one of the main drivers of innovation in this field. Reports from the metallurgical industry show that the percentage of recycled materials used in the production of steel grating has risen by over 30% in the last five years. This change not only reduces the damage to nature but also aligns with the worldwide campaign to support circular economic systems. Modern coatings, for example, galvanized finishes, improve steel grating’s resistance to corrosion and wear thus making it more appropriate for the harsh conditions while at the same time doubling its lifetime.

Moreover, CAD (computer-aided design) is one of the digital tools that is bringing tremendous changes in the customization aspect of production. The engineers now can design according to their requirements for various applications (such as industrial platforms and architectural projects) down to the very detail. Recent research findings say that nearly forty percent of the steel grating work is done with some form of customization which shows the significance of adaptability in the infrastructure of today.

These developments are proof of the steel grating industry’s dedication to confronting the challenges of the times, as the superhighway of steel grating technologies is laid for a future that is more environmentally friendly and serves a wide range of sectors worldwide.

Eco-Friendly Materials in Grating Production

I believe that using green materials in grating production is essential to reduce the negative environmental impact and promote sustainability. The use of recycled metals, energy-efficient manufacturing processes, and non-toxic coatings are some of the ways we can create long-lasting, superior grating solutions, all while generating less waste and using fewer natural resources. This way of doing things does not only take care of the environment but also is in line with the rising demand for eco-friendly building practices.Future Directions in Steel Grating Sizes and Applications

Future Directions in Steel Grating Sizes and Applications

Customization and Versatility

The steel grating of the future will not only be able to offer the most customized sizes and designs but would also be more at the same time. The specific manufacturing process enables a specific width, length, and spacing that can be used in different applications, such as energy, industrial processing, and architecture.

Lightweight Grating for Specialized Uses

Technological developments in materials are enabling lighter steel grates without sacrificing strength. Grates of this kind can be found in the transportation and aerospace industries, where they meet lightweight yet durable requirements.

Integration of Advanced Coatings

The combination of epoxy and galvanized finishes is playing a major role in steel grating's usage by providing the coatings that increase resistance to corrosion and wear. These grating solutions have been revitalized and their performance has been reassured, even in extreme conditions such as offshore oil rigs and chemical factories, thanks to these innovations.

Adaptability for Smart Infrastructure

The advent of smart technology is necessitating the development of steel grating types that can house sensors, monitoring devices, and other IoT devices. This not only enables real-time detection of structural issues but also enhances safety in applications such as bridges, industrial platforms, and urban infrastructure.

Environmentally Friendly Manufacturing

The next generation of steel grating solutions is to be made of recycled steel along with other eco-friendly production methods that will save energy. New, smaller, and more modular grating sizes are being developed, which will greatly minimize material waste and thus would be an environmentally friendly option for construction and industrial projects.

The integration of these advancements shows how industries evolve and that their demand for the triad of functionality, sustainability, and innovation in steel grating manufacturing is heard.

Frequently Asked Questions (FAQ)

What are the standard steel grating sizes available?

Standard steel grating sizes generally range from 12 to 48 inches wide and 36 to 120 inches long. Typical heavy-duty thicknesses are 1 to 2 inches. These dimensions are suitable for several applications like platforms and walkways, providing safety and long-term use.

How can I customize steel grating sizes for my project?

Customized steel grating sizes can be obtained from a supplier that manufactures grating products to the specific dimensions of your project. You can have a unique size that is just right for your application such as stair treads and industrial platforms, and so on.

What types of steel are used in bar grating?

Bar grating is generally produced from different steel types, with carbon steel, galvanized steel, and stainless steel being the most used. Among the three, carbon steel is most commonly used for its strength and affordability; on the other hand, galvanized steel is well-suited for outdoor applications, where its corrosion resistance is highly valued. Stainless steel is the go-to option when toughness and a pleasing appearance are required.

Are heavy-duty welded steel bar gratings available?

Indeed, heavy-duty welded steel bar gratings are available and designed to withstand heavy loads in industrial applications. These gratings are made of high-strength bars welded together, providing long-lasting durability and stability for use in areas such as catwalks and mezzanines.

What is the significance of serrate and tread in steel grating?

Serrate shows the notched surface of the steel grating, which provides better traction and slip resistance. Tread patterns are very important for pedestrian safety in moist regions. The two properties improve the safety margin of grating usages thus making them suitable for walkways and stair treads.

How does galvanizing improve the durability of steel grating?

Galvanizing is a process that applies a zinc coating to the steel surface to protect it against rust and corrosion. The method has a significant impact on the durability of steel grating, making it suitable for outdoor or harsh-conditions use. Hot-dipped galvanization is known to be particularly effective at providing long-lasting protection.

What are the advantages of using metal grating in drainage systems?

Using metal grating in sewage channels ensures effective water flow and the grating's load-bearing capability. Clogging doesn't occur in open spaces, so dirt won’t accumulate. Moreover, drainage grating made for such purposes is usually constructed from tough materials such as stainless steel or galvanized steel.

Is steel grating compliant with the Disabilities Act?

Steel grating can be manufactured to be ADA-compliant, allowing people with disabilities to access walkways and ramps. Safety measures such as serrated surfaces and appropriate spacing between bars are among the factors to consider when complying with the Disabilities Act's standard safety measures.

Recently Posted

-

Aluminum Steel Grating: A Comprehensive Guide to Grating Products

December 23, 2025In industrial flooring applications, safety, durability, and versatility are the most essential characteristics. Among materials, Read More

Read More -

Understanding 316L Stainless Steel Bar Grating: Properties, Applications, and Advantages

December 22, 2025The 316L stainless steel bar grating is the material most people choose when applications are challenging and require high perform Read More

Read More -

Essential Steps and Tools for Building a Fence: A Complete Guide

December 19, 2025No matter the reason, outdoor areas that are more private, secure, or simply well-delineated, a fence will certainly be a very nic Read More

Read More -

Metal Fencing Options: Choosing the Right Type of Metal Fence

December 18, 2025Metal fences do not only serve as barriers but also as a mixture of functionality, durability, and style that can change any prope Read More

Read More