Understanding Steel Grating Price: Factors, Applications, and Buyer Tips

Steel grating is an excellent and durable material with a wide range of applications, from construction to industrial facilities. Still, understanding steel grating pricing can be complex due to many factors that affect costs, not to mention the vast number of applications to consider. This blog article will help you understand steel grating pricing by covering the principal reasons the product is expensive, the numerous applications it is used in, and essential tips for buyers who want to be well-informed before making a purchase. Whether you are a contractor, project manager, or just curious about steel grating, this guide will be handy, offering insights on how to strike a balance between quality and budget. Continue reading to find out everything about the prices of steel grating and how to make your buying decisions better. Find more info now.

Key Factors Influencing Steel Grating Prices

Material Type

One of the main factors that significantly determines the price of steel grating is the type of material used in its manufacture. In most cases, carbon steel is the less expensive option, while stainless steel is the more expensive option due to its high resistance to rust and tendency to last longer. The selection should be made according to the specific demands of the project.

Grating Style

The style of the grating, such as welded, press-locked, or swage-locked, influences its price. Welded grating is usually less expensive due to simpler manufacturing processes, whereas press-locked and swage-locked options may cost more for their precision and strength.

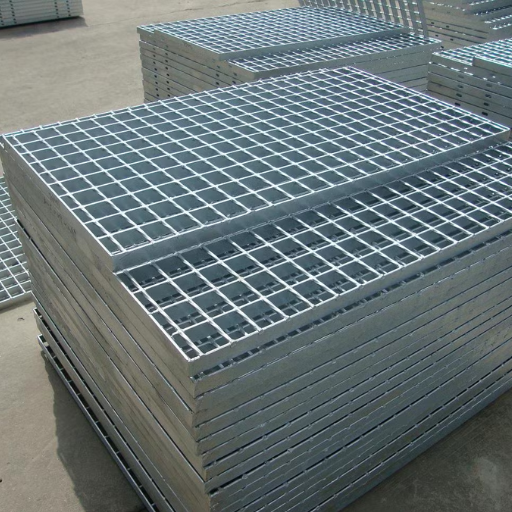

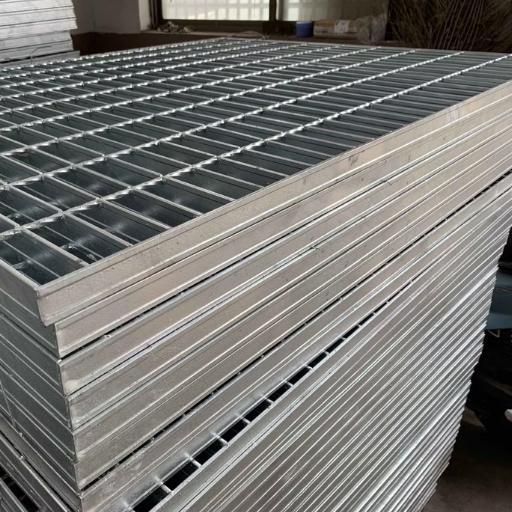

Surface Treatment

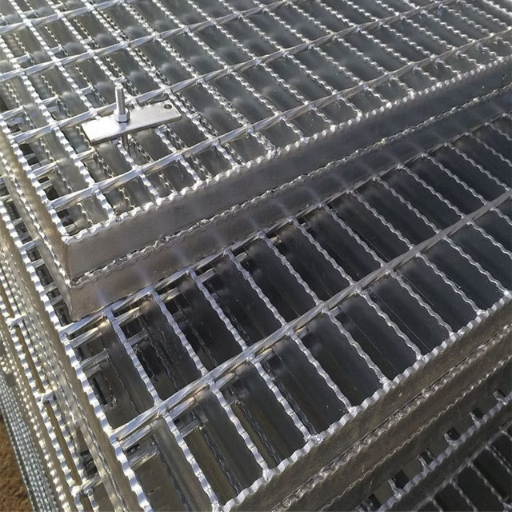

Surface treatments, such as galvanization or painting, increase the overall cost but extend the grating's lifespan by preventing rust and wear. Galvanized grating is particularly popular for its balance of durability and cost-effectiveness.

Dimensions and Load Capacity

Larger, thicker gratings, designed to support higher loads, come at a premium. Ensure the dimensions and load capacity meet your project’s needs without unnecessary over-specifications that could increase costs.

Manufacturing and Delivery Costs

Location, production complexity, and shipping distance can also influence pricing. Gratings that are custom-made or need to be shipped over long distances often result in higher overall costs. Local sourcing may help reduce these expenses.

Material Quality and Specifications

The durability, performance, and price of gratings are heavily dependent on the quality and specifications of the materials used in their production. The choice of materials for gratings is mainly dictated by the application and the environmental conditions where the gratings will be used, and the materials are usually steel, aluminum, or fiberglass. For instance:

Steel Gratings: Among all the metals, steel is the strongest and most durable, followed by aluminum. Usually steel gratings consist of carbon steel or stainless steel. The surface of carbon steel is coated to prevent rusting and corrosion, whereas corrosion-resistant stainless steel is inherently more expensive. A good example of an ASTM A36 steel, which has an average yield strength of 36,000 psi, is a common standard for strength.

Aluminum Gratings: These gratings are easy to move, which is why they are often used in portable applications. At the same time, they are corrosion-resistant, allowing them to be placed in moist or chemically exposed areas. Aluminum 6061-T6 is a commonly used alloy with a tensile strength of 38,000 psi and a strong ability to support structures.

Fiberglass Gratings (FRP): With excellent corrosion resistance, fiberglass gratings are mostly found in chemical plants, offshore platforms, and places that are usually severe in terms of chemical or moisture environments. Besides that they are non-conductors and lightweight with their load-bearing capacity being at par with metals; typical flexural strength may vary from 15,000 to 25,000 psi.

Furthermore, specifications such as bar spacing, thickness, and surface treatments come into play. For heavy-duty applications, such as vehicular traffic or industrial equipment, where large loads are expected, closer bar spacing or thicker materials are required. The application of anti-slip coatings or serrated surfaces improves safety, especially in wet or oily environments.

The process of selecting the proper material and specifications involves analyzing factors such as load capacity, environmental considerations, and budgetary constraints. Industry standards such as ANSI/NAAMM MBG 531 serve as a guide for grating manufacturers and purchasers in ensuring quality compliance, load capacity accuracy, and the overall safety of the products.

Manufacturing Processes and Their Impact

Metal grating manufacturing processes are very different from each other and the one chosen will, consequently, affect the product's quality in terms of durability, functionality, and usage. Among these are the welding grating and press-locking grating production methods, which are the two most frequently used, and we introduce the production process for each.

1. Welded Grating Production

The process consists of welding the bars perpendicularly to the plates bearing at their crossing points under wanting conditions. The welding process forms potent, durable bonds that can withstand heavy loads, making it suitable for industrial equipment and walkways. Industry statistics state that welded grating takes up more than 60% of the total market demand because of the very favorable ratio of its strength to weight, its cost-effectiveness, and the variety of applications it can be used.

2. Press-Locked Grating Production

The press-locked gratings are made by which the crossbars and perpendicular bars are joined together by applying high mechanical force. This technique consumes less labor and is used mostly in architectural projects or regions where aesthetics are prioritized. The press-locked gratings are also known for their ability to maintain tight tolerances and provide smooth surfaces, thus being virtually the only gratings suitable for commercial use.

Key Influences on Environmental Footprint

The selection of the manufacturing process is closely related to environmental impact. For instance, energy-saving welding technologies, highly automated machinery that minimizes waste are some of the measures taken by some manufacturers to be more environmentally friendly. Also, the use of recycled steel is becoming increasingly prevalent in the production of gratings, which, according to the latest sustainability studies in the metal industry, can reduce CO2 emissions during steelmaking from virgin materials by as much as 58%.

Emerging Technologies in Grating Production

Highly skilled labor, CAD software, and other recent innovations are changing the landscape of grating manufacturing by enabling faster, more precise, and more customized production. While additive manufacturing is still at the very early stages of grating applications, it holds the promise of future benefits such as just-in-time production and virtually no material usage. Global forecasts predict a steady annual growth of 3% in the adoption of automated, eco-friendly grating production technologies which means that advanced techniques would not only deliver quality but also be considerate of the environment.

In conclusion, knowledge of the different metal grating processes and their alignment with operational requirements and environmental best practices will support better choices between metal gratings intended for industrial or architectural use.

Market Demand and Regional Variations

The global market for metal gratings continues to grow, underpinned by advancements in the construction industry, the industriousness of the industrial sector, and the need for green infrastructure. The different regions show variations in demand based on economic priorities, industrial applications, and the environmental regulations in place. Below are five key points that summarize market demand and regional trends:

North America

Demand is very strong due to heavy industry and energy infrastructure projects.

Sustainable gratings will be used more and more to meet strict environmental regulations.

Europe

The construction sector is growing considerably, particularly in the UK, Germany, and France.

Production methods are becoming eco-friendly as a result of the European Green Deal.

Asia-Pacific

China and India, among others, are experiencing a surge in demand for durable, cost-effective gratings due to rapid industrialization.

The market remains active due to infrastructure development, particularly in urban areas.

Middle East & Africa

The oil and gas industry is investing heavily; therefore, there is a need for industrial gratings with features such as corrosion resistance.

The demand for architectural applications continues to grow as new residential and commercial projects come online.

Latin America

Demand for metal gratings in infrastructure projects is being driven by urbanization and the economic recovery.

Brazil and Mexico are the main players in the regional market, focusing on supplying cost-efficient, durable materials.

Types of Steel Grating and Their Applications

Welded Steel Grating

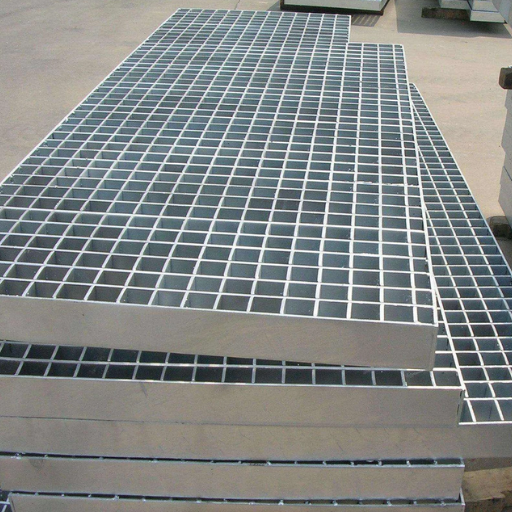

Welded steel grating is the most widely used type of grating. It consists of steel cross bars welded to the bearing bars at right angles. It is characterized by strength, durability, and easy installation. The main areas of application are industrial flooring, walkways, stair treads, and drainage covers.

Press-Locked Steel Grating

This kind of grating is made by applying pressure and precision to push the steel crossbars into the bearing bars. It has a clean look and can be found in architectural designs, public areas, and commercial projects where appearance and practicality go hand in hand.

Swage-Locked Steel Grating

This kind of grating has bars mechanically locked into the mounting bars, creating a tighter fit. It is perfect for light use, such as mezzanines, shelving, and guarding, where extra strength is not required.

Heavy-Duty Steel Grating

Heavy-duty steel grating is used only in areas requiring extreme load-bearing capacity and is thus most common in the transportation sector, e.g., bridges, airports, roads, and docks. It is defined by its heavier bearing bars and greater strength.

Aluminum Steel Grating

This grating, made from lightweight, corrosion-resistant aluminum, is the only choice for marine environments, chemical plants, and other surfaces exposed to very high moisture levels. It is a combination of toughness and difficulty in handling, hence, its acceptance in hard-to-reach places.

Steel Bar Grating: Features and Uses

Among the many industrial and commercial applications, steel bar grating is one of the most common and widely used types of flooring. It is a robust and versatile solution and also a durable and efficient choice for featuring various applications. The following points are the basic features and uses of steel bar grating:

High Strength and Durability

Steel bar grating has been specifically engineered for heavy-duty applications, which includes factory floors, loading docks, and industrial platforms. It is well able to withstand heavy loads and harsh conditions.

Slip Resistance

The serrated or textured surface makes a big difference by providing a high level of slip resistance, which, in turn, contributes to the safety of workers in certain environments where they might be exposed to wet or oily surfaces.

Easy Maintenance

Steel bar grating does not allow dirt or debris to accumulate on it so that the cleaning wouldn't be hard, and the maintenance wouldn't be constant.

Excellent Ventilation and Drainage

Being open, the design provides good ventilation and drainage, ensuring no water pooling and proper air circulation in places like wastewater treatment plants or food processing factories.

Customizable Sizing and Design

Steel bar grating can be tailored for dimensions, spacing, and surface finish to suit the project needs and thus, its versatility across many industries is further enhanced.

Stainless Steel Grating: Benefits and Markets

Stainless steel grating is a material with numerous advantages, making it highly sought after in many industries. It is corrosion-resistant, durable, and offers a superb finish, making it one of the best materials for cleansing and strengthening processes. The thorough benefits and the places that usually take up stainless steel grating are mentioned below:

Stainless Steel Grating's Benefits

Corrosion Resistance

Stainless steel has the highest possible grade of corrosion resistance which makes it applicable in places where moisture, chemicals, and extreme weather occur. Therefore, the durability of the material and the reduced maintenance costs are assured.

Durability and load capacity

Stainless steel grating is extremely strong and can be used in heavy-load areas where harsh industrial conditions prevail.

Hygiene and Cleanliness

Stainless steel grating has a smooth surface that is easy to clean and is also resistant to bacterial growth, a very important factor in the food and pharmaceutical industries.

Aesthetic Appeal

Stainless steel grating with a shiny finish enhances the contemporary, professional look of architectural projects and is preferred for commercial and residential use.

Eco-Friendly and Recyclable

Stainless steel is a material with 100% recyclability, which ultimately causes no harm to the environment, whereas in the construction and manufacturing sectors it would be an aid to eco-friendly practices.

Markets Utilizing Stainless Steel Grating

Food Processing

Food processing plants typically use stainless steel grating for its sanitary features and ease of cleaning.

Pharmaceutical Industry

Pharmaceuticals require a sterile environment, and stainless steel grating is a big help in keeping those areas clean and stable.

Chemical and Petrochemical Plants

The material's properties, such as non-corrosion and resistance to harsh chemicals, make it ideal for industries that demand a lot.

Architectural Design

Architects look to stainless steel grating for contemporary staircase, walkway, and building facade designs for its aesthetic appeal and strength.

Marine and Offshore Applications

Stainless steel grating is a great material for the marine industry as it can withstand saltwater corrosion, thus providing safety on drilling rigs and ships.

Metal Grating Options and Their Applications

Welded Steel Grating

Welded steel grating is among the most commonly used options and is recognized for its toughness and ease of processing. It is the prime choice for industrial plants, parking lots, and other applications requiring high load-bearing capacity. The rods are welded together, creating a robust lattice that provides a dependable surface.

Press-Locked Grating

Press-locked grating offers a tight, smooth surface, making it suitable for areas that require a more elegant look or non-slip applications. This type is widely used in places where appearance is essential, such as office buildings, public areas, and architectural features.

Swage-Locked Aluminum Grating

This option is a little more expensive, but on the other hand, it is lighter and ideal for areas with water, where corrosion is a major concern, such as wastewater treatment plants and pedestrian paths near riverbanks or lakes.

Fiberglass Reinforced Plastic (FRP) Grating

FRP grating can withstand chemicals and has the lowest weight among metal alternatives. It is applied in chemical plants, the food industry, and other places with corrosive agents.

Heavy-Duty Steel Grating

Heavy-duty steel grating was specifically designed to take down the maximum load-bearing requirements. It is very commonly used on industrial platforms, roads, and bridges where heavy vehicles and machinery will pass.

Comparative Pricing Across Regions and Suppliers

The cost of grating materials varies quite a bit from region to region and supplier to supplier. These differences are due to various reasons such as manufacturing costs, transport, and the demand in that location. The following is a summary of the comparative pricing details of the various suppliers and regions for the most common types of gratings:

FRP Grating (North America)

Average price range: $20-30 per square foot.

Notable suppliers: McNichols, Bedford Reinforced Plastics.

Mild Steel Grating (Europe)

Average price range: €15-25 per square foot.

Notable suppliers: Meiser, Lichtgitter.

Aluminum Grating (Asia-Pacific)

Average price range: $25-40 per square foot.

Notable suppliers: Lionweld Kennedy, Indiana Gratings.

Heavy-Duty Steel Grating (Middle East)

Average price range: $30-50 per square foot.

Notable suppliers: Saudi Gratings, Galva Coat.

Stainless Steel Grating (South America)

Average price range: $40-60 per square foot.

Notable suppliers: Metalex, Regan Industrial Sales.

These prices are intended as a rough guide only; final costs may also be adjusted based on custom specifications, discounts for bulk orders, and the delivery option selected. It is always best to request quotes from several suppliers to compare and get the best deal.

Regional Price Differences for Steel Grating

The cost of steel grating can vary widely from one area to another; this is mainly due to factors such as raw material availability, varying manufacturing costs, different labor rates, and varying market demand. Here is the new price list showing the average prices of steel grating in different parts of the world based on the latest data:

North America

Average price range: $30–$50 per square foot.

Contributing factors:

The demand is very high in the construction and industrial sectors.

Local steel production is a major factor in cutting down import costs.

Notable suppliers:

McNichols Co.

Direct Metals Company.

Europe

Average price range: €25–€45 per square foot.

Contributing factors:

Very high manufacturing standards and strict environmental regulations considerably increase production costs.

Heavy reliance on regional steel mills.

Notable suppliers:

Meiser GmbH (Germany).

Lionweld Kennedy (UK).

Asia-Pacific

Average price range: $15–$35 per square foot.

Contributing factors:

Low labor costs in countries like China and India make the production cost competitive.

The abundant availability of raw materials keeps material costs low.

Notable suppliers:

Hebei Zhenxing (China).

Yantai Xinke (China).

South America

Average price range: $40–$60 per square foot.

Contributing factors:

The very low capacity of local production encourages a high level of importation.

End-user costs are affected by taxes and tariffs on imports.

Notable suppliers:

Metalex.

Regan Industrial Sales.

Middle East and Africa

Average price range: $35–$55 per square foot.

Contributing factors:

The Gulf Cooperation Council (GCC) countries, especially, have a high demand for infrastructure development, which drives the demand.

High prices are partly due to many products being imported from Europe or Asia.

Notable suppliers:

Emirates Steel.

Saudi Steel Grating Company.

Recommendations for Procuring Steel Grating

In light of the ever-changing prices, it would be wise to:

Get prices from several suppliers not only within your area but also in other regions.

Look into additional costs such as transportation, taxes, and possibly installation to arrive at a true total cost estimate.

Try to buy in large quantities to get discounts, particularly if you are importing from countries with cheap prices like Asia-Pacific.

Supplier Comparisons: Cost vs. Quality

Choosing a steel grating supplier is always a matter of balancing between the costs and the quality taking into account the precise requirements of the project. Here are five suppliers that stand out to be mentioned, together with a very general description of what they are offering:

Saudi Steel Grating Company

Cost: Medium

Quality: Steel of the highest quality that is highly resistant to corrosion and is compliant with international standards.

Notes: The company is credited for always delivering good quality and providing excellent customer service. However, its prices may be the highest in the region.

China Grating Solutions

Cost: Low to Mid-range

Quality: The company's products are still very much competitive though they are not as good as Western products. The quality is best for bulk sales only.

Notes: Overland shipping and long delays should be factored in when buying from the Asia-Pacific region.

AMICO Industrial Products (USA)

Cost: Very High

Quality: Top, because they offer advanced customization and multiple safety features across their product line.

Notes: A wide down-to-earth application where the supremacy of performance defeats budget concerns.

European Metalworks Ltd.

Cost: Middle to Upper range

Quality: Very uniform, with premium eco-friendly materials.

Notes: Fast and dependable delivery in Europe, consistent with EU standards.

India Steel Grating Exporters

Cost: Minimal

Quality: Fair for general use, but heavy-duty ones might not have top certifications.

Notes: The cheaper the cost the better, especially when it is for a big project and there’s no budget for it.

By having a good grasp of their strengths and weaknesses, procurement managers can categorize their projects according to the criteria of cost and quality that are most important to them.

Current Trends in Steel Grating Pricing

Right now, steel grating prices are significantly affected by several key factors. To my knowledge, the cost variation of basic materials, such as iron and zinc, is the main reason for the price change. Furthermore, the global supply chain issues and the high transportation cost are among the factors that contribute to the increase of prices. However, competition among sellers in places like Asia has kept prices for ordinary-grade products relatively competitive. To get the best value, I work on the principle of balancing quality specifications with market prices and supplier reliability.

Practical Tips for Buyers

Monitor Market Trends Regularly

Being well-informed with the latest global market trends regarding raw materials like steel, aluminum, and zinc is very important. Monitoring exchanges such as the London Metal Exchange (LME) can give you a good idea of price movements and help you predict the changes.

Diversify Your Supplier Base

It is not a good idea to put all your eggs in one basket by depending on a single supplier. Involve suppliers from different parts of the world, such as Asia, Europe, and North America, to reduce the risks of supply chain disruptions and to secure the best pricing possible.

Leverage Long-Term Contracts

Take advantage of long-term contracts with reliable suppliers during times of stable pricing. It not only provides you with a safeguard against sudden price increases but also reinforces the bonds with suppliers which might lead to better service and reliability.

Invest in Quality Assurance Processes

Quality control should be a major focus of your cost management, and you should have robust quality control mechanisms in place to avoid losses from inferior materials. Work with suppliers who supply consistent quality certifications that meet your specifications.

Negotiate Freight and Logistics Costs

Transport and freight charges can significantly affect the total cost of materials. Work with your suppliers or logistics providers to develop better shipping terms, or consider combining shipments to lower total costs.

How to Request and Compare Quotes

Acquiring the best value usually entails effective quote requesting and comparison when sourcing materials or services. To make the process seamless, here are the steps to follow:

Clearly Define Your Requirements

Communicate with the suppliers a very detailed account of what exactly you need in terms of materials or services. This should include the quantities, quality standards, delivery timelines, and specific certifications or conditions required. Providing clear information will enable suppliers to give you accurate quotes.

Request Quotes from Multiple Suppliers

So you can make a better decision, go ahead and request quotations from at least 3 to 5 suppliers. This will enable meaningful comparisons of prices and services. Do not forget to involve suppliers with a good reputation and experience.

Standardize the Quote Format

It would be ideal if all suppliers presented their quotes in a common format. The format should include line items for unit price, shipping costs, taxes, and any other fees that may apply. Having a standardized format makes it easier to compare the quotes side by side.

Analyze Additional Value-Added Services

Think of the suppliers what additional services they can provide, for example, to give longer warranty periods, provide quality inspection reports, or offer payment terms that are more flexible. The add-ons can be very significant in terms of value beyond just the differences in pricing.

Compare Total Landed Costs

The comparison of suppliers should not be limited to the base price but rather to total landed costs which cover shipping, handling, import/export duties, and other related charges as well. With this comprehensive approach, you will know not only the cost but also the impact of each supplier's offer on the costs you will bear.

If you follow these steps and gather the information systematically, you will be able to determine the supplier that gives the best combination of price, quality, and trustworthiness.

Understanding Size and Dimension Requirements

Understanding the size and dimension requirements is very important in the procurement process when sourcing components, materials, or equipment. Accurate dimensions guarantee compatibility, eliminate logistical problems, and minimize the costs associated with reworks or returns. Recent reports suggest that using cutting-edge tools like laser measuring devices or 3D scanners can help in better accuracy while measuring.

Accuracy of Dimensions: Hitting the Bull’s Eye with Accurate Dimensions

Accurate dimensions ensure that the items to be sourced conform to the design and functional requirements. For example, in manufacturing, a difference of even a millimeter in parts can lead to assembly errors or a loss of product quality. Industry research indicates that around 30% of product delivery delays are due to size incompatibility in sourced components.

Standards and Tolerances

Always refer to the corresponding global standards, for example, ISO 2768 for general tolerances, or industry-specific standards for sizing. The clear specification of tolerances helps suppliers adhere to the specs and minimize variations. For instance, in the aerospace sector, the tolerance requirements are often as close as ±0.001 inches.

Shipping and Packaging Considerations

The size and weight of the items are the main factors that determine the shipping methods and costs. For bulk suppliers, merging dimensions to conform to standard pallet or container sizes can yield considerable savings. A packaging optimization calculator can be a valuable tool in the effort to reduce logistical costs. For instance, shipping fees charged by companies like FedEx and UPS depend on dimensional weight (DIM), which is a function of size and weight.

Digital Solutions in Procurement

Using software platforms such as CAD (Computer-Aided Design) and specialized dimension calculators can facilitate alignment of the design with the manufacturer via the supplier. A recent Google poll found out that among the procurement teams that employed digital solutions, 65% of them experienced a decrease in the errors in the specifications related to size.

Businesses can make their procurement process smooth, cost-effective, and consistent in delivery by combining precision and technology. The clear setting of standards and the use of modern tools ensure that every component is perfectly integrated into the larger operational framework.

Maximizing Value: Getting the Best Deal on Steel Grating

Building up on the fact that customers are the most important factor in any business, suppliers need to keep their customers happy and satisfied. One effective way to do this is through loyalty programs that offer a variety of rewards to customers who keep coming back. A company might give its customers points every time they buy its products, which can be exchanged for discounts on future purchases, freebies, or other gifts. Besides attracting new customers, offering loyalty programs also increases customer retention among those already in the company.

Get the most out of your investment by following these five important tips:

Compare Multiple Suppliers

To make it easier to get the best price, research and request quotes from various suppliers as a starting point. When doing this, also consider extra costs that might be included like shipping or customization fees, and do a background check on the suppliers' reliability and quality before making a decision on who to buy from.

Leverage Bulk Discounts

The cost of steel grating can be greatly reduced when purchased in bulk. Sometimes suppliers offer bulk discounts or tiered pricing based on volume, which eventually reduces the average cost per unit.

Specify Accurate Measurements and Specs

Make sure you provide detailed specifications for the size, type, and load-bearing capacity you want. If the specifications are accurate, this means there will be little or no mistakes, which might lead to the need for replacements; hence, it saves you money in the long run.

Take Advantage of Seasonal Promotions

Some suppliers offer discounts on their products during the off-peak season or run promotional sales. Therefore, it is wise to monitor market and sales trends so one can take advantage of low prices and buy materials during these periods.

Consider Long-Term Supplier Relationships

Trust-based relationships established with the supplier can yield benefits in the long run. Suppliers that have been in the business for long offer loyalty, better payment terms, and priority service to their repeat customers.

As long as these approaches are sustained and the procurement strategy is continually reviewed, businesses in the steel grating market can achieve the desired combination of good performance and cost-effectiveness.

Frequently Asked Questions (FAQ)

What factors determine the price of steel grating?

Steel grating price is set by numerous factors such as the material, thickness, width, length, and the type of finish like galvanization. Moreover, the ordered quantity and the grating's size (standard or custom) can be significant factors in determining the total cost. The grating type and specific placement, whether for foot traffic or heavy industrial use, are among the factors that can affect the price.

What specifications are typical for metal grating?

Metal grating specifications include the material type (galvanized steel or aluminum), the thickness of the bearing bars, the bar spacing, and the panel dimensions. Heavy-duty grating is often required for industrial use to carry loads, and the grating must pass safety tests, including ADA compliance for pedestrian areas.

Is it possible to have floor grating cut to custom sizes?

Floor grating cut to custom sizes is offered by many suppliers to meet specific project requirements. This also includes an option for cut-to-size panels that can be adjusted to fit various applications, such as drainage, platforms, and industrial equipment. Custom sizes can be part of your installation, serving both functional and aesthetic purposes.

What is the difference between galvanised and stainless steel grating?

Galvanised steel grating has a zinc coating that acts as a barrier to corrosion, making it suitable for outdoor and industrial applications. On the contrary, stainless steel grating is already the most durable among materials, especially in harsh environments. The decision between the two materials is dictated by application and environmental factors.

How do I ensure my steel grating complies with safety regulations?

To make sure that your steel grating is in accordance with the safety regulations, you should check if it is ADA compliant in the first place which is especially important in case the grating will be used in pedestrian areas. Also, verify that the grating can withstand the required traffic and load. Determining specifications and seeking suppliers' help will also help ensure safety is not compromised.

What are the most common types of grating applications?

Typical grating applications include walkways, platforms, stair treads, and drainage systems. Steel grating is widely used in industry because it is very robust, while for lighter applications, aluminum grating is often the choice. Load capacity, spacing, and environmental exposure are some aspects that may differ among individual applications.

What is the most extensive stock for steel grating that can be found?

The most extensive stock of metal grating usually includes different styles, such as serrated, smooth, and coated. The suppliers usually offer a wide range of sizes, thicknesses, and materials to accommodate a variety of applications. It is important to check whether the vendor you are dealing with has a complete inventory, as this can help you find the best match for your project.

How does the steel grating supply and inventory affect the price?

Its supply and inventory levels can substantially influence the price of steel grating. High levels of stock can also result in lower prices due to lower demand. On the other hand, if only a few styles or sizes are in stock prices of those may go up. Besides, surplus inventory held by suppliers may also provide an opportunity for cost savings if one goes for bulk purchases.

Recently Posted

-

Safety Grating: Understanding Grating Products, Plank Options, and Grip Strut Safety Grating

January 16, 2026The performance and safety of the industrial sector greatly depend on the materials used. Grating systems are among the best repre Read More

Read More -

Understanding Galvanized Grating: Benefits, Applications, and Installation Tips

January 16, 2026Galvanized grating is the best among tough, long-lasting materials. It offers strength but is not limited to it; the product's Read More

Read More -

Stainless Grating: Understanding the Benefits and Applications of Stainless Steel Bar Grating

January 13, 2026Stainless steel bar grating can be regarded as a construction material that has the highest degree of practicality—it is a strong, Read More

Read More -

Heavy Duty Grating: Understanding Grate Applications and Benefits

January 13, 2026For industrial and commercial applications, performance, longevity, and especially safety are essential and cannot be overlooked. Read More

Read More