Aluminum Steel Grating: A Comprehensive Guide to Grating Products

In industrial flooring applications, safety, durability, and versatility are the most essential characteristics. Among materials, aluminum steel grating has gained popularity for its strength, lightness, and rust resistance. This guide provides an in-depth overview of aluminum steel grating—from its key characteristics and forms to its applications in construction, manufacturing, and transport. This article is designed for contractors, engineers, and facility managers to help them find the right grating products for their specific project needs. Continue reading to learn about the revolutionary impact of aluminum steel grating on modern infrastructure and design. Find more info now.

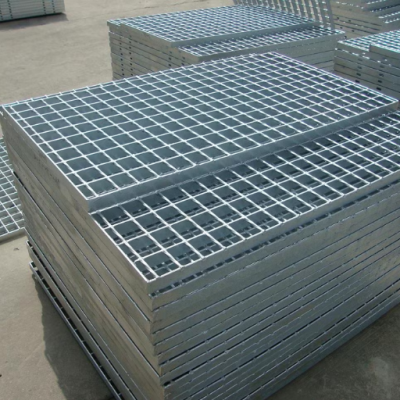

Introduction to Grating Products

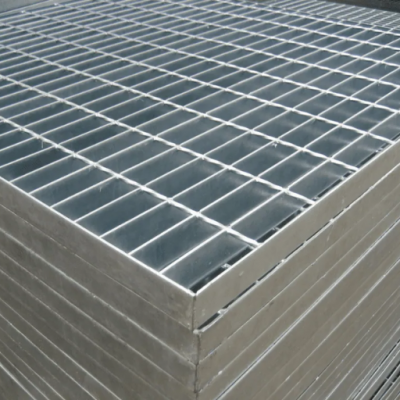

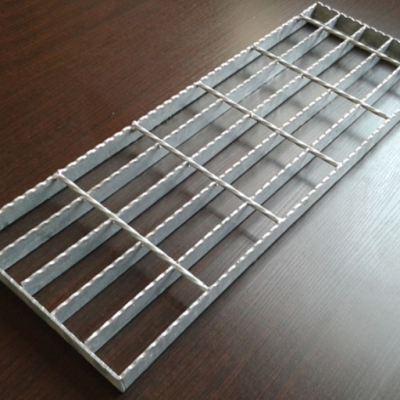

Grating products are essential materials for constructing flooring, platforms, and walkways in industrial environments. Such products are usually manufactured from aluminum, steel, or stainless steel, all of which are metals recognized for their high strength and durability. The open-grid design of the products provides excellent ventilation, drainage, and slip resistance. Their versatility has made them a standard choice across sectors such as construction, manufacturing, and transportation, all of which require the highest safety and reliability.

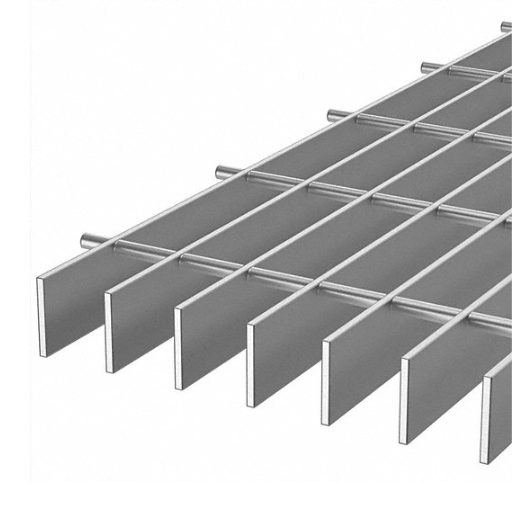

What is Aluminum Steel Grating?

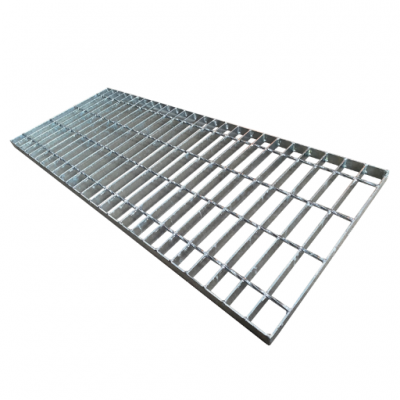

Aluminum steel grating, known for its light weight and strength, features a corrosion-resistant open-grid design, which is the main reason it is often found in places that must be both safe and well-ventilated, such as factory floors or walkways.

Key Features of Grating

Strength and Durability

Gratings are designed to withstand not only maximum loads but also challenging conditions, making them well-suited for large-scale, hard-wearing applications in industry and commerce.

Corrosion Resistance

Aluminum steel grating has a very high resistance to corrosion, which is why it is the best choice for incorporation in places where there is continuous exposure to moisture, chemicals or very hot or very cold weather.

Lightweight Design

Aluminum steel grating's lightweight makes installation and movement of the material very easy without compromising the structure's strength.

Excellent Ventilation

The open-grid design allows air to circulate and water to drain, minimizing the risk of liquid or debris accumulation.

Slip Resistance

Gratings are often designed with anti-slip surfaces, which increase safety in high-traffic areas or in areas where slippery conditions may occur.

Benefits of Using Metal Grating

Durability and Longevity

Even in extreme environments, metal grating is highly wear-resistant. Steel and aluminum are able to last a very long time, thus, cutting down the frequency of replacements and contributing to cost savings in the long run.

Versatility

Metal grating can be used in a broad range of applications such as; industrial platforms, walkways, drainage covers, and ventilation screens. Its flexibility makes it a reasonable choice across sectors such as construction, manufacturing, and oil and gas.

High Load-Bearing Capacity

Metal grates with high strength-to-weight ratios can easily support heavy loads, including machinery, vehicles, and foot traffic, making them well-suited for both light- and heavy-duty infrastructure.

Corrosion Resistance

The waterproofing of the galvanized or stainless steel grating is aimed at us having the most challenging conditions surrounding us, e.g., lack of water, chemicals, and super high or low temperatures, and still performing optimally.

Cost-Effectiveness

With very durable products in the long run, little maintenance staffing, and easy installation, metal grating can be considered as the cheapest option for companies whose goal is to increase safety and functionality.

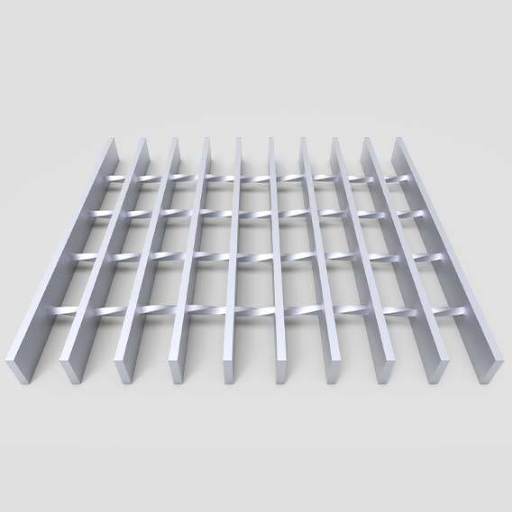

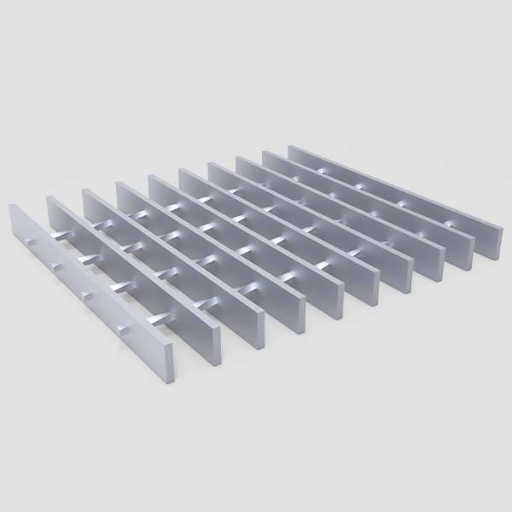

Advantages of Aluminum Bar Grate

Lightweight

In addition to being easy to handle, aluminum bar grating's weight reduction reduces structural loads, which is especially beneficial in certain applications.

Corrosion Resistance

Aluminum is a metal that, by nature, will always be alive and always protect itself with a rust-proof and corrosion-proof oxide layer formation. This picture guarantees life and less maintenance, particularly where moisture or chemicals are present.

High Strength-to-Weight Ratio

Despite being a lightweight material, aluminum is powerful and can support heavy loads. This is the reason why it is used in the industrial sector where strength and reduced weight are both required.

Non-Sparking Characteristics

Aluminum bar grating represents a non-sparking material, which is a vital safety criterion in those places where sparks could ignite hazardous substances like chemical plants or oil sites.

Aesthetic Appeal

The natural look of aluminum gives off a smooth, modern appearance. Besides, anodizing or powder coating can easily enhance it further giving a customized look which makes it perfect for functional as well as architectural applications.

Lightweight Properties

Aluminum bar grating has gained recognition across many fields for its light weight and associated advantages. Here are five lightness-related characteristics and facts about aluminum bar grating that are worth bearing in mind:

Structural Load Reduction

Aluminum being light totally reduces the weight on the supporting structures, thus it can safely be used for industrial and commercial platforms, walkways, and even mezzanines.

Installation Is No Problem

Aluminum bar grating, with its weight reduction compared to steel and other materials, is easier to handle, carry, and install. This is the end result: a mountain of cost and time savings from labor.

Portability Enhanced

Lightweight aluminum grating can be moved or its configuration changed whenever necessary; thus, it is a versatile choice for temporary or changing sites.

Transport Fuel Efficiency

Lightness results in lower costs and better fuel efficiency during transport, which is especially significant in the case of large quantity shipments, representing a lot of savings over time.

Heaviness-Free Durability

Aluminum grating, while being lightweight, holds strong to its spec of durability and corrosion resistance, thus offering a long useful life without the drawback of adding unnecessary weight.

Durability and Corrosion Resistance

Aluminum grating is widely recognized for its remarkable longevity and non-corrosive properties, thus becoming a reliable material for different places. The following five crucial aspects, along with their respective data points are illustrate these traits:

Corrosion Resistance in Hard Conditions

Aluminum, because of its nature, creates a protective oxide layer that lets it remain rust and corrosion resistant even in difficult settings such as maritime or industrial.

Durability

Research has shown that aluminum buildings can last more than 50 years with minimal maintenance, making them the most durable material by a wide margin.

Little Maintenance

Aluminum grating, owing to its corrosion resistance, requires little to no maintenance per the established plan, thereby reducing operational costs throughout its service life.

Chemical Resistance

Exposure to acids and salts, which often lead to the degradation of other materials, does not affect aluminum; hence, it is a good choice for chemical processing plants.

Functioning under Very High or Very Low Temperatures

Aluminum does not lose its durability or become less rigid when subjected to extreme heat; rather, it performs well in both scenarios.

Cost-Effectiveness Over Time

Aluminum, the most striking metal, offers a key advantage: its cost-effectiveness over its lifetime. Apart from the initial price which is higher than some traditional materials like steel or plastic, the quality features of aluminum assure manufacturers substantial savings in the long run with repairs and replacements. For example, recent studies in the industry indicate that aluminum's corrosion resistance can add up to 30% to the life span of buildings and products, and thus, costly repairs or replacements are avoided.

Moreover, aluminum, being a metal, is 100% recyclable and it always comes back to the market as good as new, which certainly makes it an eco-friendly and economically sustainable decision. Per the Aluminum Association's estimates, about 75% of aluminum produced so far can still be put to use, which again signifies its strength and the cost-efficient recycling techniques, amongst others. Notably, only about 5% of the energy required for primary aluminum production is used in recycling, thereby reducing production costs and environmental impacts.

On top of that, one of the properties of aluminum that makes it lightweight is its contribution to cost savings in transportation and aerospace industries. Using aluminum in vehicles and aircraft can lead to better fuel efficiency, losing weight, which in turn can significantly lower operational costs. Full-scale studies have shown that a 10% reduction in vehicle weight can increase fuel efficiency by 6-8%. The result is that savings would be amassed considerably over the years. Thus, the excellent trio of durability, recyclability, and efficiency makes aluminum a really cost-effective solution for many applications.

Applications of Grating in Various Industries

Grating, a material known for its durability, strength, and environmental resistance, is highly versatile and therefore widely used across sectors. The following are the five major 5 applications of grating in different industries:

Industrial Flooring

The most common use of grating is as industrial flooring in factories, power plants, and workshops, where safety and durability are the main concerns. This is due to the material's high load-bearing capacity and slip-resistant surface, which makes it ideal for such areas.

Oil and Gas Platforms

Grating is a standard material for walkways and platforms on offshore oil rigs and gas rigs. Its resistance to corrosion guarantees long-lasting use in severe marine environments while keeping high structural strength throughout use.

Construction and Infrastructure

Grating is used in a range of applications, from bridges and drainage covers to building exteriors and facades. Its light weight and custom-made design permit it to be easily incorporated into structures without making them heavier.

Mining Operations

Grating is used in the mining sector for fresh air ventilation, screens, walkways, and flooring. Its high load-bearing and chemical-resistant properties make it suitable for the harsh conditions prevailing in this sector of mining.

Shipbuilding and Marine Industry

Grating is a standard material in the shipbuilding industry for decks, ramps, and all kinds of stairs, etc. and it is among the main properties of the material to prevent slip that safety on board is ensured, especially during wet and slippery conditions.

The applications mentioned above indicate that grating can adapt to changing conditions and supports operations and safety across different industries.

Industrial Applications

Construction Industry

Grating is extensively employed in the construction industry for flooring, walkways, and maintenance platforms. The open grid structure lets water run-off and air circulate, while the strong and long-lasting materials allow for heavy-duty work to be done. Industry reports indicate that the construction industry accounts for about 35% of global grating market usage.

Oil and Gas Sector

Grating is the material of choice in oil rigs and refineries for platforms and walkways due to its high load-bearing capacity and anti-corrosive nature. It is the most reliable and practical solution in areas with chemicals and extreme conditions. The oil and gas sector accounts for nearly 25% of global grating demand.

Shipbuilding and Marine Industry

Non-slip grating helps keep areas on board ships safe by preventing slips and falls on ramps, stairs, and decks, particularly in wet conditions. This application is critical to maritime safety standards, and the marine industry is estimated to account for about 15% of the global grating market.

Manufacturing and Processing Plants

Grates are common in factories and large processing plants, where they cover openings above machines and provide ventilation, among other uses. Its resistance to wear and tear and its adaptability to different applications are the factors that lead processing plants to consume about 10% of the global grating output.

Wastewater Treatment Facilities

Grates are a critical component of wastewater treatment plant infrastructure, providing both sturdy access platforms and drainage systems. Its high resistance to corrosion and chemical attack ensures it performs well in hostile environments over the long term. The wastewater treatment industry accounts for 8% of the global grating demand.

Commercial Uses

Shopping Malls

Grating is an integral component of shopping malls, primarily used for ventilation, drainage, and aesthetic flooring solutions. Its durability and modern design make it a preferred option in high-traffic areas. This is responsible for nearly 12% of grating applications in commercial use.

Office Buildings

Grating is the material of choice in office buildings for raised floors, service platforms, and server rooms. The material's strength and ventilation properties facilitate efficient infrastructure maintenance. Office building applications account for about 10% of grating consumption in commercial spaces.

Parking Structures

Grating is the most critical material in parking structures, used for ramps, drainage systems, and walkways. Its slip- and corrosion-resistant properties enhance safety and longevity, making it a segment accounting for about 15% of the commercial grating market.

Airports

Airports have incorporated grates into service tunnels, maintenance areas, and drainage systems. The material's ability to carry heavy loads and its wear resistance are major contributors to its widespread adoption, accounting for nearly 9% of the total commercial grating market.

Retail Complexes

Grating is used by retail complexes to improve drainage systems, strengthen service areas, and incorporate unique design features into modern architecture. The retail sector is estimated to contribute approximately 11% to the total commercial grating market.

Residential Applications

Grating is quickly becoming a common choice in residential applications due to its multifunctional, durable, and aesthetic qualities. Below are the most critical applications for residences listed:

Drainage Systems

One of the major fields for grating application in residential areas is drainage systems. Driveways, patios, and gardens are common areas where grates are used to prevent flooding and enable effective water management. In these systems, lightweight materials are often used to facilitate installation.

Balconies and Decking

Grating gives an option of strong and slip-resistant surface to balconies and decking areas. The capability of grating surface to allow water pass through minimizes pooling and hence enhances safety during wet conditions.

Ventilation Covers

Grating has been one of the major factors in the residential area for air and vent covers where good ventilation is achieved but aesthetic appearance is maintained. Such covers are often designed with durability and less maintenance in mind.

Basement Access Flooring

Grating is a perfect option for basement access areas. This sturdy and durable flooring can support heavy weight while offering excellent airflow to prevent moisture buildup.

Poolside Areas

Grating is the material of choice around swimming pools as it facilitates drainage and minimizes slip surfaces. It ensures prompt drainage of excess water, thereby maintaining safety and cleanliness around the pool.

Comparison of Aluminum and Steel Bar Grating

Parameter | Aluminum Bar Grating | Steel Bar Grating |

|---|---|---|

Weight | Lightweight, easy to handle | Heavier, more robust |

Corrosion Resistance | High, ideal for wet environments | Moderate, prone to rust |

Strength | Good strength-to-weight ratio | Higher overall strength |

Density | 2.7 g/cm³ | 7.8 g/cm³ |

Maintenance | Low, requires minimal upkeep | Higher, needs regular maintenance |

Cost | Generally more expensive | More affordable |

Recyclability | Easily recyclable | Recyclable |

Applications | Marine, chemical, lightweight structures | Heavy-duty industrial, structural projects |

Non-Sparking | Yes, suitable for explosive environments | No |

Durability | Durable, but less impact-resistant | Highly durable and impact-resistant |

Aluminum vs. Carbon Steel Bar Grating

Parameter | Aluminum Bar Grating | Carbon Steel Bar Grating |

|---|---|---|

Weight | Lightweight, easy to handle | Heavy, robust |

Corrosion Resistance | High, ideal for wet environments | Low, prone to rust |

Strength | Good strength-to-weight ratio | High overall strength |

Density | 2.7 g/cm³ | 7.8 g/cm³ |

Maintenance | Low, minimal upkeep required | High, needs regular maintenance |

Cost | Generally more expensive | More affordable |

Recyclability | Easily recyclable | Recyclable |

Applications | Marine, chemical, lightweight structures | Heavy-duty industrial, structural projects |

Non-Sparking | Yes, suitable for explosive environments | No |

Durability | Durable, less impact-resistant | Highly durable and impact-resistant |

Performance Factors

Selecting aluminum or carbon steel bar grating is not easy, as the performance factors are numerous and sometimes conflicting. Nevertheless, the following five major performance factors can be used to guide the decision-making process:

Weight

Aluminum: Its low weight makes installation and handling easier, especially in weight-restricted areas.

Carbon Steel: In terms of weight, it is more than aluminum, and thus it is stronger and more durable, but at the same time, it is also harder to install.

Strength

Aluminum: A tough material that maintains its strength in a lighter form, thus it is suitable for loads up to moderate requirements.

Carbon Steel: A material that can easily bear even the most enormous weight loads, thus its primary use in industrial and heavy-duty applications.

Corrosion Resistance

Aluminum: Its natural corrosion resistance makes it ideal for outdoor or moisture-prone environments, such as marine or poolside applications.

Carbon Steel: Without the coating or galvanization, it is easily corroded; it needs to be protected in environments that are of a harsh nature.

Cost

Aluminum: The expensive production process and material properties drive the price up in the initial stage.

Carbon Steel: It is typically the cheapest and most accessible option, though the additional coating costs for corrosion resistance may limit its use.

Maintenance

Aluminum: It is a metal that requires minimal maintenance; it retains its original properties and continues to function reliably in most conditions over time.

Carbon Steel: To prevent rust and extend its service life, it must be maintained regularly or recoated.

The above performance factors, among others, are critical to selecting the most efficient and cost-effective material for your bar grating needs.

Choosing the Right Material for Your Needs

The choice of the right material for your bar grating is primarily based on an understanding of your project's specific requirements, the environmental and operational conditions in which it will be installed, and related factors. To support each claim with recent information and arguments:

Load-Bearing Requirements

Aluminum Bar Grating: It is commonly used in these kinds of applications where there is a need for about the same capacity as a lighter load and at the same time corrosion resistance is a significant concern. The aluminum grating can bear human or occasional car traffic. Thus, it can be used for walkways, platforms, and such.

Carbon Steel Bar Grating: It is always associated with the highest strength, and up to the maximum limit of load-bearing, carbon steel is the material of choice for heavy-duty applications like floors, the use of machines, and shipping docks.

Corrosion Resistance and Climate

Aluminum: It has been established that this material can withstand marine environments and high-humidity regions without special treatment, owing to its inherent resistance to corrosion and oxidation. For example, the lifespan of aluminum grating in marine installations has been decades, with little wear.

Carbon Steel: the downside of it being stronger is that it still has to be protected, either by being galvanized or coated, against the attack of moisture or chemistry in the case of aggressive environments. Some studies assert that hot-dip galvanizing can increase the lifespan of carbon steel by 20 years or more even in the case of moderate environments.

Cost Effectiveness

When taking into account both the initial and the life costs, aluminum is quite often the one that comes out cheaper for projects that have to deal with the highest maintenance and replacement costs. On the other side, carbon steel may not be very costly initially; however, the following maintenance costs have to be considered, especially for outdoor or high-moisture applications.

Weight Considerations

In case weight is an important factor in your project design, for instance, in mobile or temporary installations, then the lightness of aluminum will be its strongest point. Research has shown that aluminum is up to 3 times lighter than carbon steel in similar applications which causes transportation and installation costs to reduce considerably.

Durability in Harsh Conditions

Tests done by independent parties have shown that the bar grating made of aluminum really keeps its structural integrity over time even in places where there is salt spray, chemical spills, and UV rays. On the other hand, carbon steel may be sturdy but it also faces the risk of rapid decay if its protective coatings are compromised.

In making your choice, it is essential to weigh these aspects against the specific project conditions you have. For example, a heavy industrial site may prefer carbon steel for its strength, while an offshore or coastal operation would benefit from aluminum’s corrosion resistance and low weight. The utilization of latest material advancements along with project-specific requirements will ensure cost savings, longevity, and operational efficiency. Always consult material specification sheets and seek expert advice to ensure you get the best for your investment.

Frequently Asked Questions (FAQ)

I-bar: What is an i-bar grating and how does it differ from an aluminum i-bar grating?

I-bar or an I-bar grating is a type of bar grating where the cross-section of the load-bearing bars is in I-shape, which provides a superior strength-to-weight ratio than flat or rectangular bar types. The term i-bar is typically used when speaking about I-shaped or I-section cross-section grating, which denotes the specific cross-section of the load-bearing bars and is often confused with the term aluminum i-bar grating. It includes aluminum bearing bars along with cross rods or swages to create panels that are light, corrosion-resistant and recyclable. Among the merits of the aluminum i-bar over others, one can point out, for instance, that it is non-sparking, easier to handle for installation, and often the material of choice for foot traffic areas, platforms, stair treads, and covers over trenches located in corrosive environments.

Aluminum i-bar grating: What are the criteria for selecting the right aluminum i-bar grating panel for walkways and platforms?

The right aluminum I-bar grating panel selection boils down to reviewing the different parameters, i.e., load-bearing and also specifications, which consist of live and dead loading, spacing of bearing bars, the pattern of cross bars, size of the panel, and the need for serrated surfaces for resistance against slipping. You should also keep in mind such factors as the American disabilities act requirements and those of pedestrians as well in terms of bar spacing and surface traction, and go for the plain or serrated surface finish based on that. Also, consider the fittings like clips and plates, which ensure secure, flush-top installations, and whether cut-to-size fabrication or custom panels are required for your facility.

Bar grating products: What are the different material types and finishes in bar grating products?

Bar grating products are available with three core material options: aluminum, galvanized steel, and stainless steel. The finishes include plain mill (Unprocessed) surface, galvanized (hot-dip or electro-galvanized), and serrated surface, which provides greater traction. Choose from press-locked, swage-locked or weld-locked manufacturing processes. For harsh conditions, corrosion-resistant aluminum or stainless steel is often advised, while galvanized steel is a budget-friendly alternative for various industrial applications.

Select: How bearing bar spacing and rectangular bar selection influence loading and strength?

The separation of bearing bars and the bearing bar profile (rectangular, I-bar, or round) directly affect the load capacity and the amount of bending or deformation of the material under load. To make it more explicit; denser spacing of bars increases the load capacity and also prevents the grating from failing in a plate-like manner, while on the other hand, lighter spacing minimizes weight and cost, but at the same time, lowers the capacity. The rectangular bar or rectangular bearing bars are widely used to achieve even load distribution; but one should always consult grating specifications and load tables in order to match the panel selection to one's loading and span requirements.

I-bar: Is it better to use a serrated surface or a plain surface grating for slip resistance on stair treads and walkways?

For traction and slip resistance, the serrated surface grating outperforms the mill or plain surface grating, particularly in wet, oily, and icy conditions. Serrated aluminum i-bar grating or serrated galvanized steel is generally recommended for escalators, pedestrian walkways, and platforms where slip resistance and compliance with the Americans with Disabilities Act (ADA) are priorities. It is essential to note that serration shortens the life of the footwear and may increase the likelihood of dirt accumulation compared with plain surfaces.

Aluminum i-bar grating: What are the different fabrication options, such as press-locked, swage-locked, and welded, that exist for aluminum i-bar grating?

The production techniques available for aluminum i-bar grating include press-locked, swage-locked, and welded (or swaged) constructions. The press-locked grating mechanically locks the cross bars into the bearing bars, providing uniform strength and a neat appearance. The swage-locked and swaged options are somewhat similar in that both involve the deforming of the bearing bar around cross rods to form a joint that is very strong and secure. The choice of the construction method primarily depends on the expected strength, appearance, thickness of the panel, and load-bearing requirements.

Recently Posted

-

Understanding 316L Stainless Steel Bar Grating: Properties, Applications, and Advantages

December 22, 2025The 316L stainless steel bar grating is the material most people choose when applications are challenging and require high perform Read More

Read More -

Essential Steps and Tools for Building a Fence: A Complete Guide

December 19, 2025No matter the reason, outdoor areas that are more private, secure, or simply well-delineated, a fence will certainly be a very nic Read More

Read More -

Metal Fencing Options: Choosing the Right Type of Metal Fence

December 18, 2025Metal fences do not only serve as barriers but also as a mixture of functionality, durability, and style that can change any prope Read More

Read More -

How to Set Up a Fence: Build a Fence from Start to Finish

December 17, 2025Erecting a fence can completely transform your garden and provide you with privacy, safety, and a defined area. It is a great do-i Read More

Read More