Aluminum & Steel Bar Grating In-Stock: The Essential Guide to Bar Grate Solutions

Aluminum and steel bar grating are the only materials that offer such unparalleled functionality and durability for industrial flooring, drainage systems, or load-bearing applications. If you are running a large construction project or just looking for a reliable solution for a small installation, the right choice of bar grating is a must. This guide will serve as your reference for distinguishing the key differences, advantages, and uses of the aluminum and steel bar grating available in stock. From selecting the most appropriate material to revealing the different application areas of these products, we will guide you through all the necessary information. Get prepared to see how grating can serve your project needs with both efficiency and style. Find more info now.

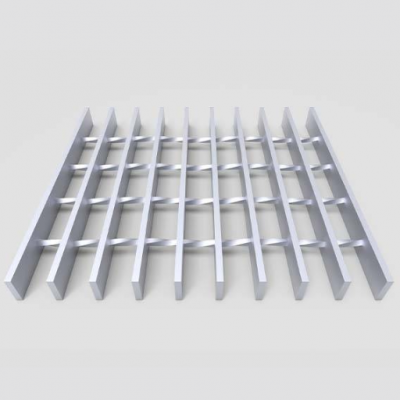

Introduction to Bar Grate Solutions

Bar grating is a remarkable solution for offering long-lasting, strong, and efficient surfaces for flooring and platforms in industrial, commercial, and architectural applications. Most common materials are aluminum and steel, and each one has its unique merits. Aluminum grating is lightweight, resistant to corrosion, and perfect for moisture or chemical environments. In contrast, the mill finish steel grating has strength and durability, thus can be used for heavy-load applications. The solutions are adaptable and can effortlessly conform to the given needs of the different projects.

The Importance of Bar Grating in Modern Construction

Bar grating is a strong, versatile, and functional material that plays a critical role in modern construction. It is used in a variety of ways and industries, thus providing support and features that are mainly associated with quality and safety. Below are the five most important details and data points that indicate the significance of bar grating in construction:

Structural Strength

Heavy loads, light ones, and everything in between can be supported by bar grating, which makes it perfect for industrial floors, catwalks, and platforms. For instance, depending on the setup, almost all kinds of steel can hold 7,000 lbs per square foot and even more, thus providing security even in tough places.

Corrosion Resistance

Aluminum bar grating is often found in chemical plants or coastal areas because it can resist not only rust but also the degradation caused by the environment. So, it is good to have this material as an investment in the site, for there will be no need for maintenance or repair for many years to come.

Enhanced Safety

Bar grating's non-slip surface is one of the best features of this product. It gives a more secure foothold for the workers in dangerous places thus lessening the chances of accidents. However, serrated grating is a still better option for boosting traction.

Ventilation and Drainage

Air, water, and light can all easily pass through bar grating due to its open design. This property makes it very useful in areas like walkways of wastewater treatment plants or even in stormwater management systems where these three factors are of utmost importance.

Customization and Versatility

Bar grating can be designed according to the requirements of the project and thus, can be manufactured in any way. It is also possible to get custom sizes, materials, and finishes that will fit not only specific dimensions but also resistance requirements ensuring compatibility with lots of architectural styles.

These benefits further emphasize the critical role played by bar grating through safety, efficiency, and adaptability in the construction projects of modern times.

Applications of Aluminum and Steel Bar Grating

In the industry of aluminum and steel bar grating the properties of the materials such as durability, lightness, and resistance to environmental factors made them highly versatile, hence, the widespread use in different industries and applications. Here are the five main applications:

Industrial Platforms and Catwalks

The main usage of bar grating in industrial areas is for making heavy-duty platforms and catwalks. The open-grid design provides slip resistance and at the same time allows for efficient drainage, thus it fitted in factories, power plants, and refineries where this is required.

Drainage Covers and Trench Flooring

Aluminum and steel grating are often applied to drainage systems, which are characterized by a strong yet lightweight structure that can carry heavy loads while allowing proper water flow. They are found in parking areas, roads drainage systems, and plants treating wastewater.

Stair Treads

Bar grating is among the first materials that come to mind when discussing stair treads in commercial and industrial settings. Its slip-resistant surface can be used in both indoor and outdoor applications where safety is a concern; it can even tolerate wet or oily conditions.

Security Fencing and Screens

The fencing and screening applications for aluminum and steel grating are based on the strength and ability to withstand harsh conditions. These materials are especially preferred in factories, storage facilities, and power plants when it comes to security.

Walkways and Ramps

Bar grating in the form of walkways and ramps is found in public areas, construction sites, or industrial centers and is valued for its durability and safety. The ability to carry large foot traffic while being resistant to environmental wear guarantees the reliability of long-termuse.

The aforementioned applications point to the fact that aluminum and steel bar grating are the versatile materials that occupy a central position in the industrial, commercial, and public sectors.

Overview of In-Stock Availability

By offering a wide range of industrial-grade aluminum and steel bar gratings, we have made it possible for various projects to utilize our materials, from corporate use to municipal construction projects. The variety of sizes and kinds of finishes ensures we can cater to almost every requirement. For the time being, the following items can be shipped out right away:

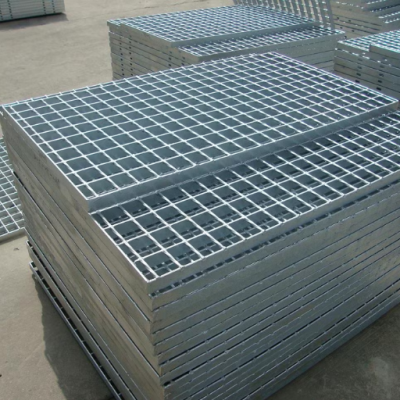

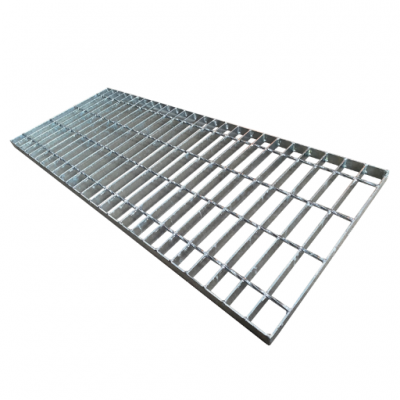

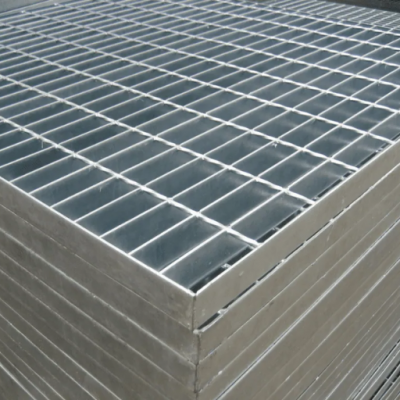

Steel Bar Grating

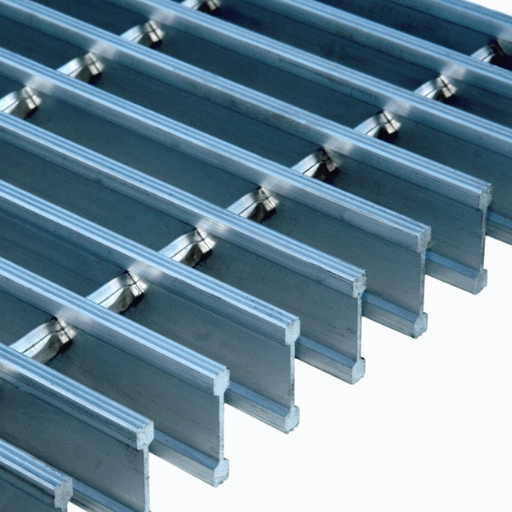

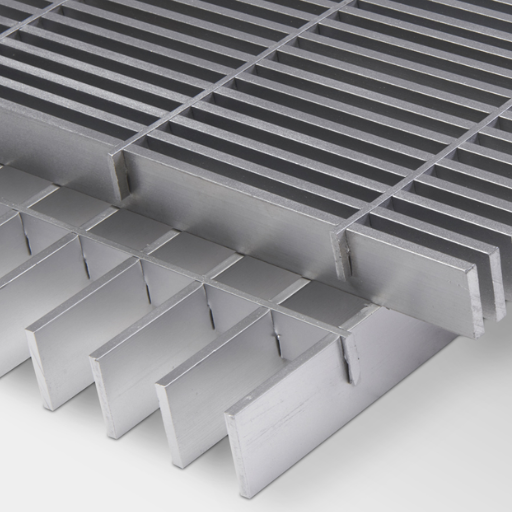

Type: Welded, Press-Locked, and Riveted

Sizes: From standard 3/4” to super strong 1-1/2” for heavy-duty use

Finish Options: Unpainted, Galvanized, or Custom-coated

Current Stock: 5,000+ square feet of it ready to ship out.

Aluminum Bar Grating

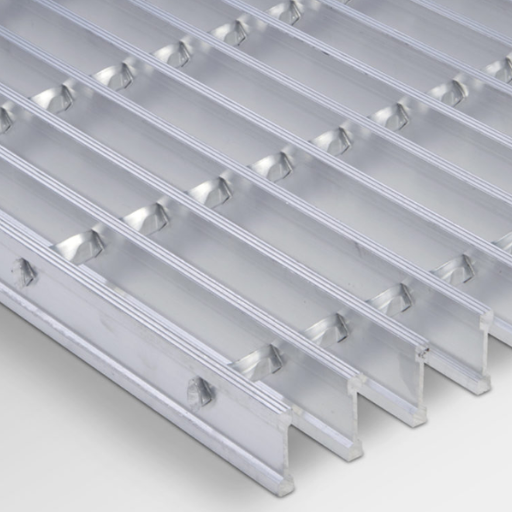

Type: Swage-Locked and Press-Locked

Sizes: Popular height profiles, made-to-order according to project needs

Finish Options: Mill finish or anodized for improved resistance of rust

Current Stock: Over 3,000 square feet to be sold.

Specialty Products

Stair Treads with serrated surfaces for more protection against slips

Customized Panels cut to the required sizes

Special orders, usually handled within 3–7 business days depending on the difficulty.

Thanks to our inventory management system, you will always be up to date on product availability. For immediate stock updates, quotes, or orders, please reach out to our customer service. Additionally, we collaborate with reliable suppliers in order to deliver large or custom orders quickly and effectively.

Benefits of Aluminum and Steel Bar Grating

Durability: Aluminum bar grating and steel bar grating are both very strong and resistant to wear, which makes them suitable for areas with a lot of traffic and heavy load applications. Steel gives the most durability, while aluminum is excellent at resisting oxidation and is, therefore, a good choice for outdoor applications that are subject to moisture.

Lightweight Design: Aluminium bar grating is a lot lighter than its steel counterpart; therefore, its handling, transportation, and installation have become very easy, and at no point was the structural integrity compromised.

Corrosion Resistance: Aluminum grating is impervious to rust and corrosion, hence it is considered as the best option for that kind of environment or location with constant water exposure. On the other hand, the steel grating can be galvanized in order to have more corrosion protection.

Versatility: The materials mentioned above are very flexible, and they can be made to suit different applications such as industrial flooring, platforms, walkways, and drain covers, among others.

Cost-Effectiveness: The bar grating of both aluminum and steel are budget-friendly options that will come handy in the long run as they will slash maintenance costs and the demand for replacing with new ones due to their extended lifetimes amidst unfavorable conditions.

Durability and Strength

Aluminum and steel bar grating are recognized for their exceptional durability and strength, making them ideal for heavy-duty applications. Steel grating, particularly carbon steel, boasts remarkable tensile strength, often exceeding 70,000 psi, depending on its composition and manufacturing process. This allows it to handle substantial loads, withstand high-impact forces, and perform consistently in demanding environments such as industrial facilities, warehouses, and transportation infrastructure. Aluminum grating, while lighter than steel, offers impressive strength-to-weight ratios. It is resistant to corrosion, thanks to its natural oxide layer, which makes it suitable for marine environments, chemical plants, and areas exposed to harsh weather conditions. According to recent industry studies, aluminum grating typically exhibits a yield strength of 20,000 to 40,000 psi, depending on the alloy used, striking a balance between durability and weight reduction. Both materials also excel in longevity under challenging conditions. Steel, when galvanized or coated, resists rust and wear, extending its service life significantly in outdoor or moisture-prone environments. Similarly, aluminum’s inherent corrosion resistance ensures long-term performance with minimal maintenance. By selecting the appropriate grating type for specific applications, industries can maximize operational efficiency and minimize replacement costs over time.

Aluminum and steel grating are highly praised for their incredible durability and strength, which makes them very suitable for heavy-duty applications. Steel grating, especially carbon steel, has a very high tensile strength, that in some cases can be even more than 70,000 psi, depending on the type and process of manufacturing. So it is able to bear heavy loads, resist high-impact forces, and also perform well in the toughest scenarios like industrial plants, warehouses, and transport infrastructure.

Aluminum grating, although lighter than steel, still gives very good strength-to-weight ratios. It also does not get corroded since it has a natural oxide layer which makes it ideal for the ocean, chemical plants, and places experiencing extreme weather conditions. Recent reports from the industry show that aluminum grating usually has a yield strength of 20,000 - 40,000 psi based on the alloy used and this gives it a nice combination of durability and weight reduction.

Moreover, both materials also stand out in terms of their lifespan even in the most difficult conditions. The service life of steel that is galvanized or coated, becomes more resistant to rust and wear and thus it prolongs significantly in outdoor or moist regions. Likewise, aluminum has a natural corrosion resistance that guarantees its long-term performance without requiring much maintenance. If the right grating type is chosen according to the application's needs, then industries can not only enhance their operational efficiency but also cut down their replacement costs over time.

Versatility in Applications

Industrial grating is a remarkable product that can provide different solutions to different sectors, mainly because of its strength, durability, and versatility. Below are the major areas where the use of industrial grating is still highly recommended:

Walkways and Platforms

Grating is usually the safest option and non-slip surfaces for the workers even in places of danger in industries. According to statistics, already more than 65% of heavy-duty industries are making use of steel grating for their walkways in order to improve safety standards.

Drainage Systems

Grating is not only a supporting element for the drainage systems but also an important factor in the whole system that allows water and dirt to get through in a very efficient manner. For example, reports on the drainage of cities indicate that during heavy rainfalls use of grating in urban areas can result in a reduction of up to 40% in the flooding risks.

Machine Covers and Safety Barriers

Besides being used as machine covers, grating also helps in keeping employees away from dangerous parts of the machines and thereby accidents in the workplace are reduced. Research shows that there is a decline in injuries related to machinery by 30% in factories where aluminum grating is installed as safety barriers.

Ventilation Flooring

Like the installations of grating in power plants and storage facilities, the installations of grating in efficient ventilation areas are the same because the grating flooring solutions are not only for air circulation but also for easy access to the heat source. The data collected from thermal plants indicates that when ventilating floor solutions are used the cooling efficiency is improved by 25%.

Grates and Trench Covers for Bridges

Grating is a perfect choice that is strong enough for weighty yet light applications. Grating provides a reliable cover for bridges and trenches as it is able to support heavy loads while maintaining the strength of the structure. The results of the tests conducted in the field indicate that galvanized steel grating can endure loads exceeding 12,000 lbs. per square foot.

The capability of grating to be put into various applications allows the industries to maintain safety and efficiency in their operations by helping them use its advantages.

Cost-Effectiveness Considerations

The cost-effectiveness evaluation of grating solutions depends on several critical factors such as material lifespan, maintenance, and installation efficiency. Grating materials have, among others, galvanized steel, which has a very good resistance to corrosion hence no service limitation, a reduction in long-term replacement, and a repair cost. Recent standard conditions suggest that galvanized steel grating can last up to 25-50 years according to the industry data, thus emphasizing the importance of its durability.

Moreover, grating has the advantages of being lightweight as compared to solid flooring substances and this not only leads to transportation cost savings but also allows for easier and faster installation. According to recent market reports, skilled labor savings of up to 30% can be realized through the use of lightweight materials for installation.

Grating’s low maintenance requirements, besides its durability and handling ease, have been its main feature in the cost-effectiveness of the product. In the past, industries have undergone continuous inspections and cleaning throughout the year to maintain the optimal condition of the grating surface. Eventually, such maintenance practices would cause the opposite outcome - i.e., the grating being very costly in upkeep. Thus, industries might soon have to adopt cleaning and inspection practices less frequently to the extent of them saving ongoing costs.

The above-depicted scenarios have led to industries claiming substantial total operational expense reductions thanks to grating. A 2023 analysis by construction engineers, for instance, says that if steel grating is used instead of traditional concrete coverings on the projects then the project costs can be reduced by nearly 20% - taking into account the saved material, reduced labor efforts, and longer lifecycle performance. The above-mentioned benefits speak for themselves which is the reason why more and more sectors are opting for grating solutions that do not only meet but also exceed the budgetary constraints and high-performance standards.

Comparative Analysis of Aluminum vs. Steel Bar Grating

Parameter | Aluminum Grating | Steel Grating |

|---|---|---|

Weight | Lightweight, 1/3 weight of steel | Heavy, higher weight |

Corrosion Resistance | Excellent, ideal for marine environments | Requires coating to resist corrosion |

Strength | Moderate, suitable for light applications | High, ideal for heavy-duty applications |

Durability | Long-lasting, minimal maintenance | Durable but needs regular maintenance |

Cost | Higher initial cost, lower maintenance cost | Lower initial cost, higher maintenance cost |

Ease of Installation | Easy to handle and install | Challenging due to weight |

Aesthetic Options | Customizable finishes, anodized options | Limited aesthetic flexibility |

Environmental Impact | Highly recyclable, eco-friendly | Recyclable, but heavier carbon footprint |

Applications | Marine, architectural, lightweight needs | Industrial, high-load, heavy-duty needs |

Maintenance | Minimal, simple cleaning | Regular cleaning and coating required |

Performance Characteristics

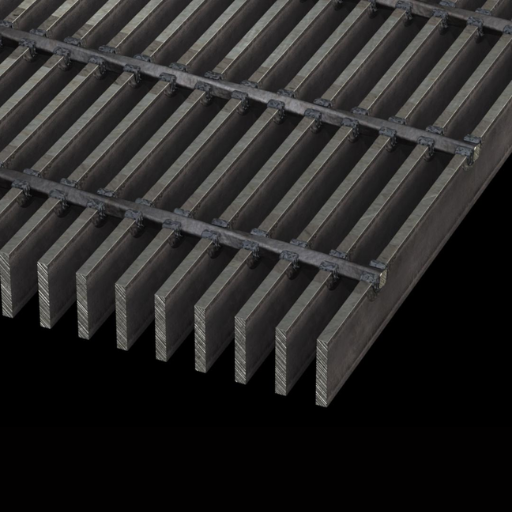

Strength-to-Weight Ratio

Compared to steel, bar grating has a greater strength-to-weight ratio in the case of aluminum. As an illustration, the grating in steel can endure tensile strength of up to 36,000 psi, thus becoming the choice for heavy-duty applications, whereas aluminum grating with the tensile strength of 22,000 psi is more suitable for lightweight tasks.

Corrosion Resistance

Aluminum grating is the best option when it comes to corrosion resistance as it has a natural oxide layer. It can be used in environments with moisture or chemicals without any negative effects. On the contrary, steel grating that has not been treated is going to rust and lose its strength, thus requiring galvanization or coating to keep up in these conditions.

Durability

Steel grating is the most durable material and, therefore, the best choice for heavy load industrial applications. Its structural integrity will last for several decades, while aluminum grating will eventually succumb to wear and tear in such environments.

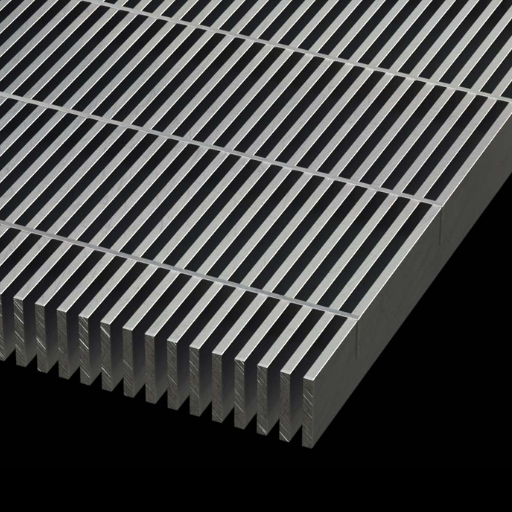

Weight

Aluminum is the metal that is totally opposite to steel in terms of weight. It can be handled and installed with ease, thus being a perfect option for performances that require the lowest weight. To illustrate, aluminum is about 33% of steel in weight.

Cost-Effectiveness

In general, the choice of steel grating will lead to lower total project costs, especially for the material part, in large-scale industrial projects. The initial higher cost of the aluminum grating can, however, be offset over time by the lower maintenance costs associated with the alloy's corrosion resistance.

Maintenance Requirements

Steel and aluminum grating have different maintenance needs, which are largely determined by their material properties and the types of their rides.

Steel grating requires frequent maintenance to prevent rust and corrosion, especially in humid or outdoor environments. A coat of galvanization simply on steel grating is the protection layer that one can stay with for around 20-50 years, depending upon the factors like the place's exposure, but the coating should be periodic and the checking done so to keep up both the lifetime and the strength of the structure. In accordance with engineering norms, using wire brushes or pressure washers for routine cleaning is one way to help get rid of the debris and thus prevent corrosion from accumulating.

Aluminum grating with the opposite scenario is a bit different, as it comes with the major virtue of the natural resistance to corrosion, thus requiring less maintenance than steel grating. The barrier that the oxide layer forms on the aluminum surface serves to to protect it from being degraded. By simply rinsing the aluminum grating with water and, every now and then, using non-abrasive cleaners to maintain its appearance and operational capability, one will be just fine. A recent research pointed the fact that the maintenance expenses for aluminum grating systems can be up to 40% reduced over 20 years if compared to untreated steel.

The two materials require ongoing safety evaluations to confirm that the steel and aluminum grating can withstand traffic and load applications. Choosing the right material and following a proper maintenance schedule will not only keep the grating systems durable but also ensure they perform well while incurring low long-term costs.

Typical Use Cases for Each Material

Aluminum Grating Use Cases:

1. Corrosive Environments Walkways

The grating is ideal for environments with abundant moisture, chemicals, or saltwater, e.g., dockyards and chemical factories. Its long-lasting performance, due to its non-corrosive nature, ensures minimal replacements.

2. Lightweight Platforms

Grating is often found in the industrial sector where weight is an issue. The lightweight nature of aluminum makes it suitable for use in mezzanines and temporary structures.

3. Architectural Applications

Aluminum grating is used in decorative facades, sunshades, and ventilation screens for its artistic look and its ability to be manipulated.

4. Food Processing Facilities

Its cleaning ability and rust resistance make it suitable not only for cleanliness and washdown but also for the food industry.

5. Cooling Tower Platforms

Aluminum is the surface exposed to both water and high humidity, making it the superior choice for cooling tower applications.

Steel Grating Use Cases:

1. Heavy-Duty Industrial Flooring

Very common flooring today in factories, warehouses, and so on; its load-bearing capacity is the reason behind it.

2. Ramps Vehicle Access

Not only is steel grating exceptionally tough, but it is also durable enough to withstand vehicle traffic, making it ideal for ramps and loading docks.

3. Construction Sites

It is often used as temporary flooring and a supporting structure because it is strong and inexpensive.

4. Oil and Gas Facilities

In these industries, steel grating is the only option because it can withstand heavy loads and extreme conditions.

5. Public Infrastructure

Essentially used on bridges, for drainage covering, and pedestrian crossing, where the ability to support a lot of weight becomes critical.

The Importance of In-Stock Bar Grating

Having readily available bar grating in stock is paramount to supporting a full spectrum of applications in various industries. The immediate supply of bar grating can greatly help to avoid project delays, increase operational efficiency, and satisfy urgent needs. Below is the list with details about the importance of having bar grating in stock:

Minimizing Downtime

Projects that depend on bar grating as a critical component face slight delays, if any, when materials are immediately available, which in turn supports well-managed timelines and smooth workflows.

Cost Efficiency

The bar grating in stock helps prevent additional procurement costs associated with fast shipping or unplanned sourcing from suppliers farther away.

Meeting Safety Standards

Having a stock of bar grating permits the swift replacement of grates in busy or risky areas that have become worn or damaged thus ensuring that safety regulations are complied with.

Flexibility Across Industries

The bar grating stock caters to the diverse requirements of sectors such as construction, industrial facilities, and transportation infrastructure, thereby enabling versatility in applications.

Adaptability for Emergencies

Unforeseen situations, such as sudden repairs or natural disasters, require immediate provision of bar grating, making stock availability a significant factor in emergency planning.

Project Efficiency and Quick Turnarounds

The grating of the stocked bar has the greatest impact on project efficiency and fast return times. Suppliers will be able to extend the manufacturing and shipping lead times, reducing lead times by a significant amount. The latest industry information indicates that when projects use stocked materials, their timelines can be cut by 30% compared to those made with custom-ordered solutions.

Moreover, prefabricated grating keeps the production process running smoothly, as he/she does not experience any problem due to lack of material. For example, in the construction industry, where delays may result in heavy financial losses, access to stocked bar grating will therefore enable continuous progress and compliance with deadlines. A recent study found that material supply companies were 20% more likely to complete their projects on time; thus, their significance is supported by the ready availability of materials.

In addition, with reference to stocked bar grating, the compatibility between standard sizes and specifications eliminates the need for extensive customization, allowing quicker implementation across diverse projects. This efficiency not only saves time but also reduces overall costs, creating an ideal balance between quality and budget.

Impact on Supply Chain Management

One factor that significantly affects supply chain management is the availability of stocked bar grating, which leads to greater efficiency, fewer delays, and better project results. The following are five key details along with data points that illustrate this impact:

Reduced Lead Times

Lead times are reduced by at least 30% with the immediate availability of stocked bar grating, which is particularly important for time-bound projects.

Inventory Optimization

By using pre-stocked materials, companies can significantly reduce the costs of excess inventory, thereby enhancing the efficiency of the entire supply chain.

Improved Collaboration

The availability of compatible, standard-sized materials improves communication and cooperation among suppliers, contractors, and project managers by making it easier to work together and by simplifying processes.

Cost Savings

Cut down on material customization and speed up the delivery of standard products, which in turn will lead to an average project cost savings of 15% and allow resources to be allocated more efficiently.

Risk Mitigation

The continuous supply of stocked bar grating lessens the risks that material shortages and delays will cause and thus projects are kept on time and within budget.

All these factors, taken together, show that stocked bar grating contributes to a more stable and well-functioning supply chain management system.

Benefits of Having Metal Bar Grating Readily Available

Faster Project Execution

The use of metal bar grating, which is readily available, allows projects to be developed quickly, as there will be no delays due to waiting for materials. Such being the case, it positively affects lead times and ensures construction timelines are strictly adhered to, thereby encouraging on-time project completion.

Cost Savings on Material Procurement

The availability of grating eliminates the need for custom orders and quick shipping, thereby resulting in cost savings on procurement and logistics. The supply of standard sizes in bulk generates economies of scale, leading to lower overall material costs.

Enhanced Supply Chain Reliability

The regular flow of metal bar grating serves as a buffer against supply shortages. This reliability, in turn, allows companies to continue operating without interruptions, even during high-demand periods.

Flexibility for Multiple Applications

A readily available grate can be easily shifted to different uses, including walkways, platforms, safety barriers, and drainage covers, among others. This flexibility means that the project requirements of various kinds can still be met without any wait.

Reduced Storage and Handling Costs

The continued stocking of metal bar grating renders the extensive on-site inventory management or the use of long-term storage facilities unnecessary. Companies can always take what they need from readily available stock, reducing storage costs and making inventory management easier.

Recent Trends and Innovations in Bar Grating Technology

In the past few years, the bar grating sector has experienced a revolution, mainly driven by the use of new materials, advanced manufacturing techniques, and the push toward sustainability. Below are the recent developments and groundbreaking innovations that are changing the landscape of the sector:

More Durable and Corrosion-Resistant Materials

The production units are increasingly adopting advanced materials such as stainless steel alloys, fiberglass-reinforced plastics (FRP), and powder coating to resist corrosion. For instance, the use of FRP grating, which is very light and non-corrosive, has been on the rise in industries that use it for marine, chemical, and wastewater applications.

Personalization via Digital Design

The primary advantages of CAD (Computer-Aided Design) technology are that it allows for the exact customization of the bar grating according to customer specifications, ensuring a high-quality fit, and that it enhances the product's operation. Smart manufacturing enables rapid prototyping, thereby shortening production times and increasing efficiency.

Green Manufacturing. Manufacturers worldwide are adopting green practices, including recycling metals and reducing power consumption during production. According to a 2022 industry report, almost 30% of grating products are made from recycled materials, reflecting market demand for green alternatives.

The Use of Smart Features

Electronic freight systems with sensor bar grating are new types of grating systems that can measure the weight and condition of the structure. These real-time feedback systems are vital, especially for major infrastructure projects such as bridges and heavy-duty factory floors.

Bar Grating to Be Light and Strong

Materials science is a continuously developing field that is advancing the production of lightweight yet super-strong grating solutions. A case in point is the aluminum bar grating, which has an excellent strength-to-weight ratio and is therefore extensively used in the transportation and power industries.

Laser-Cutting Techniques and Automation

High-tech appliances used in today's manufacturing plants employ automated laser-cutting technology to create flawless, accurate grating shapes. Not just does automation facilitate precision, but it also minimizes wastage, thereby maximizing cost-effectiveness.

According to a study by Market Analysis Weekly, the global bar grating market is expected to grow substantially, with a CAGR of 5.6% from 2023 to 2030. Investment in upgrading urban infrastructure, together with the growth of industrial and commercial use, is the main reason for the rise. The industry continues to meet the changing demands of the market through its constant endeavor to stay ahead in material innovation and by applying the latest technologies.

Advancements in Aluminum and Steel Bar Grating

The aluminum and steel bar grating have been areas of great interest over the last few years, with the main focus on the durability of the materials. The introduction of high-strength alloys into aluminum grating is a significant achievement that helps keep the material lightweight while increasing its resistance to corrosion and wear. Such characteristics make aluminum grating a choice for the harshest environments, such as marine and chemical processing plants and wastewater treatment facilities.

The reverse is true for steel bar grating, which has innovations in galvanization and coating technologies. Processes for hot-dip galvanization have been precisely adjusted to improve corrosion resistance, thereby prolonging the life of steel grating even in challenging environments. Along with that, the development of composite coatings has enabled steel grating to deliver superior performance in industrial applications that require both strength and longevity.

Recent figures show that at the end of the year 2022, the global market for aluminum and steel bar grating was close to 1.1 billion dollars and it will grow in the same manner for the next ten years. Among other things, the increasing use in the construction, energy, and transportation industries has been the main driver of growth. Moreover, manufacturers are using the latest laser-cutting and robotic welding technologies to the fullest in the production of grating solutions with precise engineering. These innovations not only enable greater customization but also allow a grating to fit perfectly to specific architectural or industrial requirements.

The eco-friendly production methods are another trend that cannot be overlooked. The companies have been implementing recycling plans for aluminum and steel, which have been very effective in reducing greenhouse gas emissions and helping them reach their sustainability targets. Industries in various regions of the world are increasingly inclined towards bar grating that meets environmental standards, and thus the demand for such innovative products continues to grow.

Innovative Designs and Finishes

Bar grating designs and finishes have been a source of inspiration for me to develop solutions that are not only practical but also good-looking. The use of modern materials and custom patterns has enabled me to meet the particular needs of various projects. Moreover, the application of extraordinary finishes, such as powder coatings or anodized layers, not only enhances durability but also creates a smooth, contemporary appearance. My commitment to quality and functionality in aesthetics has been aided by these innovations, which have enabled me to provide personalized, top-notch products.

ADA Compliance and Safety Standards

Complying with the ADA (Americans with Disabilities Act) and safety standards is crucial to creating environments that are accessible, equitable, and safe for all, including people with disabilities. Among the significant requirements of the ADA, public places must provide wheelchair-accessible ramps, doorways at least 32 inches wide, and push-type door handles. Restrooms must have grab bars and at least one stall that is appropriately sized for a wheelchair.

According to the latest figures from the U.S. Department of Justice, in 202,3 more than 70% of public places had significantly upgraded their facilities to comply with ADA standards. Besides, slip-resistant flooring and properly marked walking surfaces are necessary for the safety of the area, especially when wet or very crowded. For example, a study conducted by the National Safety Council found that workplaces with slip-resistant surfaces compliant with the ADA standard reported a 30% decrease in falls and fall-related injuries.

Modern compliance also increasingly relies on innovative measures, such as digital accessibility features. These are the braille signage, audible alerts, and website designs that support screen-readers and are thus accessible to all. The mentioned improvements ensure that interactions between people with impairments in sight or hearing and their environment are safe and that they can do so independently, thus aligning with the ADA's mission. By making the above standards their priority, the projects not only meet the requirements mentioned above but also promote inclusivity, safety, and good design across all aspects of the projects.

Frequently Asked Questions (FAQ)

What kinds of aluminum bar grating are there?

You can find our aluminum bar grating products offering a variety of options, differing in thickness and bearing bar spacing. All these options are designed to accommodate various load-bearing applications and can be customized to meet unique customer requirements. In fact, you can pick among a range of thicknesses, bearing bar spacings, and sizes to fit your project needs.

What is the difference between aluminum bar grating and steel bar grating?

The aluminum bar grating, compared to steel, is really kerf-friendly: it is lightweight and rust-free, and it is suitable for places where steel doesn't add weight while enhancing the structure's strength. On the other hand, heavyweight options like galvanized steel and carbon steel are most sought after for demanding applications where the load, without which the structure cannot stand, is the primary consideration. The two are available in multiple sizes and finishes.

What is the bearing bar spacing for aluminum grating?

The bearing bar spacing for aluminum grating depends on the application and load requirements. Different bearing bar spacings are used for various applications, including floor, walkway, and mezzanine. It is essential to select the proper spacing for both safety and performance.

Can aluminum bar grating be customized?

Aluminum bar grating can be customized to your satisfaction; we will cut it to your specifications. Whether you need precut sizes or custom cuts, we can meet your project's needs. The gratings you receive will fit perfectly in your allocated space, thanks to our fabrication services.

What are the advantages of using aluminum I-bar grating?

The primary advantages of aluminum I-bar grating are its lightweight structure, corrosion resistance, and a flexible, long-lasting profile. The I-bar shape provides greater load-carrying capacity without sacrificing the tough-to-slip surface, making it suitable for a range of uses, including human-traffic areas like walkways and stair treads.

Are there ADA-compliant aluminum grating options?

Yes, we have aluminum grating products that comply with the ADA regulations. For safety and accessibility, these items have been provided with non-slip surfaces and appropriate bar spacing, explicitly designed for public areas. It is crucial not only to meet the legal standards but also to be accessible to everyone by using a gate that is compliant with the ADA.

What is the best finish for steel bar grating?

The surrounding environment usually determines the finish that is most suitable for a steel bar grating. In somewhat corrosive environments, galvanized grating is best because of its Coated Protection, whereas stainless steel's superior corrosion resistance and pleasing appearance are its strengths. Thus, choosing the right finish prolongs the life of your grating products and reduces maintenance.

How do I buy aluminum and steel bar grating online?

Aluminum and steel bar grating can be easily and conveniently purchased from our online store. Different options are available, including precut dimensions and custom cuts that conform to your project specifications. Browse our extensive selection of grating products and place your order from home or the workplace with ease.

What are typical applications for aluminum bar grating?

Aluminum bar grating is used in a variety of applications, including walkways, platforms, stair treads, and drain covers. It has become ubiquitous due to its lightweight properties and resistance to corrosion, making it suitable for both industrial and commercial environments and providing safety and durability, which are the necessary characteristics demanded by pedestrian and load areas.

Recently Posted

-

Installing a Fence: DIY Guide & Tips to Install a Fence Easier

December 31, 2025Building a fence can be a challenging task, but it offers the owner several functional and aesthetic advantages, especially for th Read More

Read More -

Understanding Basketball Court Fence Cost: Factors, Materials, and Installation

December 29, 2025The fence is usually the most critical component in ensuring a basketball court is secure and functional when building or upgradin Read More

Read More -

Architectural Stainless Steel Grating: The Modern Choice for Durable and Stylish Designs

December 26, 2025Architectural stainless steel grating has become the top choice for contemporary designers and architects for its combination of s Read More

Read More -

Aluminum Steel Grating: A Comprehensive Guide to Grating Products

December 23, 2025In industrial flooring applications, safety, durability, and versatility are the most essential characteristics. Among materials, Read More

Read More