Steel Grating Design: Innovations and Applications in Industrial Settings

Steel grating has long been an essential, widely used product in the industrial sector due to its strength, durability, and utility. But, the latest implications in design and technology are reshaping its use and making it a more versatile solution that can be applied to different industries. Steel grating nowadays, besides making work environments safer and improving energy efficiency, is also a sign of industrial needs and the development of engineering skills. The present blog post intends to highlight the most recent steel grating design advancements and their remarkable implementation along with their big advantages to the global industries. If you are looking for information on new materials, high-tech production methods, or new application areas, this guide will provide thorough insight into the future of steel grating in industrial settings. Find more info now.

Understanding Steel Grating

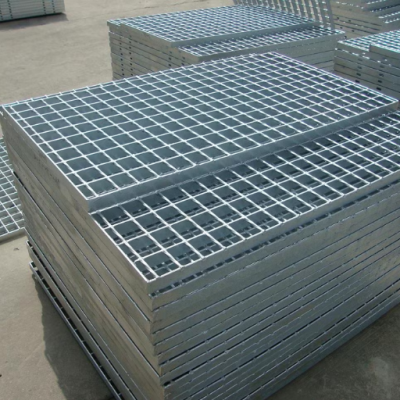

Steel grating is a highly durable and versatile product made by assembling steel bars crosswise and lengthwise to form a grid. It is widely accepted in industrial and commercial applications for its strong points, high load capacity, and resistance to harsh weather and other environmental factors. Amongst the typical uses are at places like flooring, platforms, stair treads, and drain covers where strong, safe and easy to clean materials are a must. By combining functionality and efficiency, steel grating has been a major factor in establishing secure, trustworthy industrial environments.

What is Steel Grating?

Steel grating is a strong, durable structural element consisting of steel bars laid in a grid pattern and can serve a variety of applications, offering high strength and excellent load-bearing capacity. Common applications for this type of grating include industrial flooring, platforms, and drainage systems.

Types of Steel Grating Products

The steel grating products are of various kinds, designed to meet the specific needs of industrial and commercial areas. Hereunder follow the most commonly used types of steel grating products, their significant technical characteristics and applications as well:

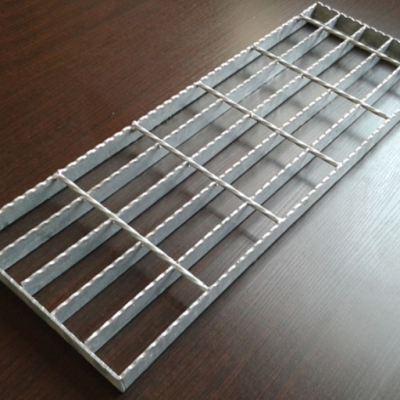

Welded Steel Grating

Welded steel grating is formed by arranging steel bars in a rectangular grid pattern and then welding them at the points of intersection. In addition to the strong bonding, it also provides high durability which makes it suitable for heavy-duty applications like walkways, platforms, and trench covers. Being a robust structure, it can bear heavy loads and is thus ideal for manufacturing, energy production, and related industries.

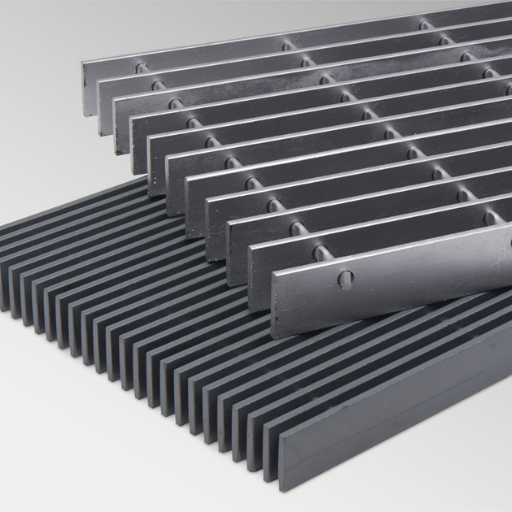

Press-Locked Steel Grating

Press-locked grating is produced by pressing and locking the cross bars into notched bearing bars. This type offers a clean and smooth surface along with uniform spacing which, while being aesthetically pleasing, does not imply giving up strength. It is very much indicative of usage in architectural works, the construction of commercial buildings, and the public places, such as bridges and urban landscaping, where the presence of aesthetic value is required.

Swage-Locked Steel Grating

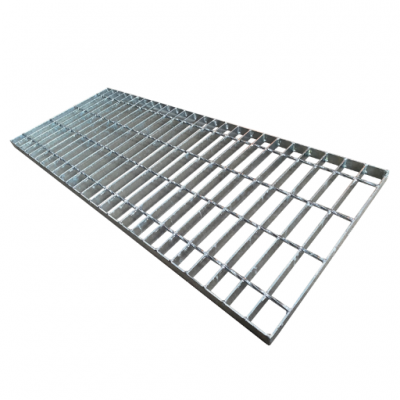

A swage-locked grating is produced by first punching slots in the bearing bars, then inserting the cross bars into the slots and tightening them to create a mechanical bond, making it difficult for the cross bars to slide out. It has the advantage of being light yet strong, making it suitable for areas such as pedestrian platforms, stair treads, and mezzanines. This grating type is also corrosion-resistant, making it suitable for coastal areas and the marine environment.

Heavy-Duty Steel Grating

Heavy-duty steel grating is designed for extreme loads that may occur in airports, highways, and industrial parks. The thicker bearing bars and wider panel spacing constructions permit applications involving not only vehicular traffic but also other high-impact activities.

Expanded Steel Grating

This kind of grating is made by cutting a sheet of steel and then stretching it in a diamond mesh pattern, which is shapped like a diamond. In addition to being lightweight, it is also cheaper; that is why it is often used for fencing, safety barriers, and ventilation grilles.

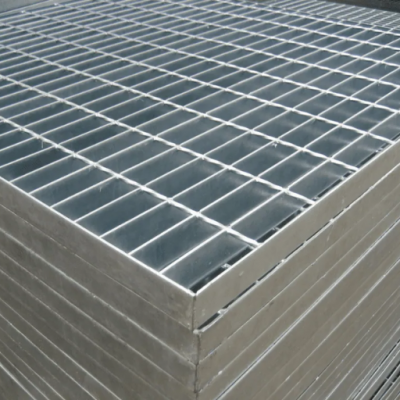

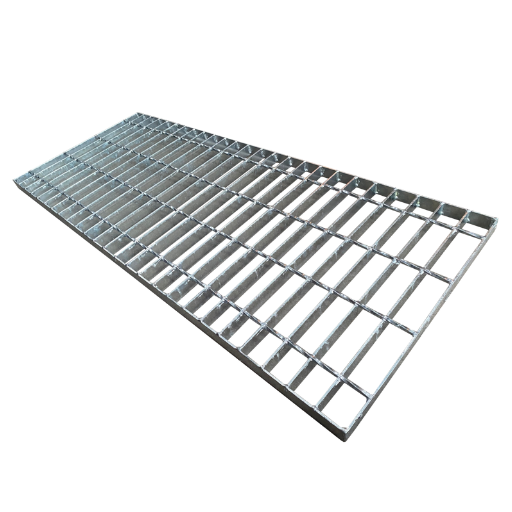

Galvanized Steel Grating

Galvanized steel grating undergoes a hot-dip galvanization process, imparting it with excellent rust and corrosion resistance. As a result, it enjoys the status of the best option for the outdoors, at places like waste treatment plants, offshore oil rigs, and chemical processing plants, all of which are so because of the nature of their processes, which involve the use of corrosive substances.

Global Market Data and Trends

According to industry analysis, the global steel grating market will expand at a compound annual growth rate (CAGR) of around 4.7% from 2023 to 2030. It is mainly the desire of the construction, oil and gas, and infrastructure development sectors for durable, low-maintenance materials that has turned the market growth around. With its large market share, Asia-Pacific is the leading region, driven by rapid urbanization and industrialization in China and India. On the other hand, industries in North America and Europe focus on high-quality, galvanized, heavy-duty grating that can withstand higher loads, as the regions have imposed stricter safety and environmental regulations.

The evolution of steel grating products is unstoppable. Manufacturers are introducing new designs and materials not only to meet the diverse demands of the different industries but also to make sustainability and cost reduction a reality.

Advantages of Using Steel Bar Grating

High Strength and Durability

Steel bar grating is a material known for its remarkable strength and durability, which is why it is used in industrial and commercial applications. Moreover, this product can withstand very heavy loads and harsh environmental conditions, ensuring long-lasting performance.

Low Maintenance

The heavy-duty steel bar grating has a long lifespan and requires little maintenance. Its property that minimizes the rust, corrosion, and wear makes it a cost-generating solution in the long run as it keeps maintenance costs low.

Superior Ventilation and Drainage

Steel bar grating has an open structure which guarantees the highest possible airflow, ventilation, and drainage. Among the features this offers, it is beneficial in an industrial setting, where the rapid flow of fluids or debris is necessary to maintain safety and sanitation.

Slip Resistance for Safety

One of the most common forms of steel grating is serrated, providing high slip resistance and therefore greater safety in wet or oily areas. This is one of the major reasons why walkways, platforms, and industrial floors are one of the main application areas for steel grating.

Versatility and Customizability

Compared to other types of grating materials, steel bar grating offers a wide range of sizes, designs, and finishes and allows for a custom-made process to meet the needs of a specific project. Its application is not limited to one industry; construction, transportation, and manufacturing can benefit from the product, as it is designed to be versatile.

Materials Used in Steel Grating Design

High-quality materials are mainly used in the manufacturing of steel grating to provide it with durability, strength, and resistance to various environmental factors. Now, let’s take a look at some of the materials that are commonly used in the making of steel grating, along with their respective characteristics:

Carbon Steel

Carbon steel is among the most utilized metal in the manufacture of steel grating because of the combination of its excellent strength-to-weight ratio and low price. This material is very much fit for heavy loads and to provide the necessary structural stability. To prolong its service life, carbon steel is often zinc-coated and the galvanized layer provides excellent protection against rust. According to industry statistics, hot-dip galvanization can keep carbon steel free from rust for 50 years in most places.

Stainless Steel

Stainless steel offers a very high level of protection against rust, making it a preferred choice for grating applications in wet, salty, or chemically aggressive environments. It finds applications in food processing, wastewater control, and the marine industry. 304 and 316 grades of stainless steel are the most common due to their high tensile strength and resistivity to rust. For instance, 316 stainless steel contains molybdenum, which increases its resistance to harsh environments with high chloride concentrations.

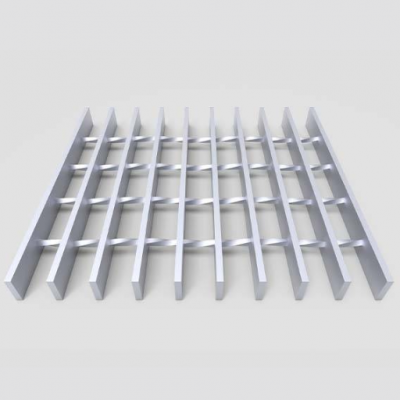

Aluminum

Aluminum is lightweight and is used in construction projects where high strength is needed but excessive weight would be a drawback. It is the best material for the protection of outdoor as well as marine installations against corrosion and at the same time, the material is easy to work with and to install. Aluminum gratings are anodized to strengthen the surface and increase corrosion resistance, and they are mostly used in the architecture and transport industries.

Fiberglass Reinforced Plastic (FRP)

Though FRP is not a metal, it is becoming a preferred substitute for steel grating designs due to its lightweight, corrosion-resistant, and non-conductive properties. Its resistance to the rigors of highly corrosive industrial environments, such as chemical plants, makes it a strong competitor with metals. FRP may be manufactured with resin systems that provide the desired fire-retardant and UV-resistant characteristics.

Galvanized Steel

Galvanized steel grating is the process of coating carbon steel with a zinc coating that protects it from rust and oxidation. This material is perfect for the outdoors or places with high humidity or water exposure. As per industry reports, galvanized steel is a balance of economy and long-term service.

These materials can be further customized in terms of dimensions, surface finish, and load-bearing capacity to meet the varied requirements of modern infrastructure. This will guarantee that they provide the desired level of functionality, aesthetics, and safety. There has been a gradual transformation in materials science, which has also given rise to new manufacturing techniques, opening up new avenues and applications for steel grating across different industries.

Stainless Steel vs. Carbon Steel Grating

Parameter | Stainless Steel Grating | Carbon Steel Grating |

|---|---|---|

Corrosion Resistance | High, due to chromium oxide layer | Low, requires galvanization for protection |

Strength | Strong, with high tensile strength | Strong, suitable for heavy-duty applications |

Durability | Long-lasting, minimal maintenance | Durable with hot-dip galvanization |

Cost | Higher, due to alloying elements | Lower, more affordable for budget projects |

Aesthetic Appeal | Sleek, modern appearance | Requires coating for polished look |

Applications | Marine, food, pharmaceutical, architectural | Industrial, manufacturing, mining, water plants |

Maintenance | Minimal, resists rust and tarnish | Requires regular inspection and coating upkeep |

Environmental Suitability | Ideal for corrosive and harsh environments | Suitable for less corrosive environments |

Weight | Lightweight, easy to install | Heavier, robust for heavy loads |

Lifespan | Longer, even in extreme conditions | Shorter without proper galvanization |

Properties of Different Steel Types

The different types of steel have varying compositions and characteristics, making them suitable for different applications. The following are five types of steel that are commonly used and their respective properties:

Stainless Steel

Properties: It possesses high corrosion resistance, durability, and a smooth surface finish. It can be exposed to humid or chemical environments because it will not rust nor stain.

Applications: It is used in food processing, medical equipment, and architectural design.

Carbon Steel

Properties: It is a robust and hard steel with very low corrosion resistance. It can be divided into several types according to the carbon content proportion, which can be low, medium or high.

Applications: It is primarily used for structural and mechanical components like beams, machines, and pipelines.

Alloy Steel

Properties: it can be chromium, molybdenum, or vanadium, for example, the addition of elements makes it stronger, tougher, and more wear-resistant.

Applications: Alloy steel is used in tools, automotive parts, and aerospace components.

Galvanized Steel

Properties: A zinc coating protects the steel from rusting and extends its lifespan. It is not only cost-effective but also easy to maintain.

Applications: It is commonly used in areas such as fencing, roofing, and outdoor structures.

Tool Steel

Properties: It has remarkable hardness and abrasion resistance, and can hold a cutting edge under high stress. It is generally mixed with tungsten, cobalt, or molybdenum.

Applications: It is perfect for cutting tools, molds, and dies manufacturing.

The distinct properties of each steel type are designed to meet the industry's specific needs, thereby providing efficiency, dependability, and longevity.

Choosing the Right Material for Grating Applications

Choosing the right material for grating applications is crucial to ensure safety, performance, and a long service life. The decision is made based on several factors; environmental conditions, load-bearing requirements, durability, corrosion resistance, and cost-effectiveness. A thorough study of the most commonly used materials for grating and their main properties is given below.

Mild Steel Grating

Example Data: Reports from the industry claim that mild steel is used in more than 50% of the world’s grating applications as the material is cheap and good for structural performance.

Advantages: Cost-efficient, and possesses high tensile strength and easy-to-weld properties.

Limitations: Gets easily rusted if left uncoated in moist or chemically aggressive environments.

Ideal Applications: Factories, warehouses, and places with little moisture or chemical exposure.

Stainless Steel Grating

Example Data: Type 316 stainless steel is the material of choice in salty environments because it offers 10 times the corrosion resistance of unprotected mild steel.

Advantages: Top-notch resistance to corrosion, high strength, and low maintenance. 304 and 316 grades are the most commonly used ones due to their performance in corrosive environments.

Limitations: The price is higher than mild steel.

Ideal Applications: In coastal areas, chemical plants, food processing units, and outdoor structures where moisture is a factor.

Aluminum Grating

Example Data: The weight of aluminum grating can be up to 65% less than that of an equivalent steel grating, resulting in a dramatic reduction in structural load.

Advantages: Light, no rust, and non-sparking; a safer choice for flammable areas.

Limitations: Not to be loaded as much as steel grating, but only half the weight-bearing capacity.

Ideal Applications: Offshore platforms, oil and gas rigs, and aerospace operations where weight is a critical factor.

Fiberglass Reinforced Plastic (FRP) Grating

Example Data: FRP grating is increasingly accepted; it is estimated to have a compound annual growth rate of 4.8% due to increased demand in the chemical and marine industries.

Advantages: Resistant to corrosion, light in weight, non-conductive, and available in several colors.

Limitations: Not very strong in terms of bearing weight and may get damaged by UV rays unless coated.

Ideal Applications: Water treatment plants, chemical processing facilities, and areas with electrical or corrosive hazards.

Galvanized Steel Grating

Example Data: According to studies on corrosion rates, galvanized steel has a service life ranging from 34 to 170 years under moderate conditions.

Advantages: Inexpensive and coated with zinc to prevent rust, plus it becomes wear-resistant in outdoor or humid conditions.

Limitations: Under adverse conditions, the zinc layer will eventually wear away, requiring reapplication or replacement.

Ideal Applications: Parking garages, building facades, and outdoor walkways.

Key Factors to Consider

Environmental Conditions: In locations where corrosion is extensive (e.g., saltwater), choose stainless steel or FRP.

Load Specifications: If dealing with heavy workloads, opt for mild or galvanized steel rather than lighter materials such as aluminum or FRP.

Budget Constraints: Mild steel and galvanized steel grating are the most economical options while stainless steel and FRP cater to niche, upscale applications with high-end pricing.

Thus, choosing appropriate material based on properties and application can help businesses not only be safe but also achieve performance at the least cost in grating installations.

Design Specifications and Tolerances

The design and selection of gratings for industrial or commercial purposes always require strict adherence to exact specifications and tolerances. This is necessary to maintain structural integrity and safety, and to meet industry requirements. Among the critical features of grating design are: load capacity, spacing, material depth, and flatness tolerances. Below we will elaborate on some key details that come from the standards and practices of the industry:

Load Bearing Capacity: Grating will cope with both, the loading with uniform distribution (UDL) and concentrated loads (CL) defined by the rules. The load range supported by the standard steel grating, for instance, is between 500 and 5,000 lbs per sq. ft., depending on the use and material thickness.

Bearing Bar Spacing: The distance between the bearing bars determines the grating's strength and safety. Common tolerances allow ±0.010-inch deviations, ensuring perfectly precise alignment that evenly distributes loads and making foot or vehicle traffic safe and secure on the surface.

Deflection Limits: According to accepted standards such as ANSI/NAAMM Standard MBG 531, the deflection of the grating under load should not exceed 1/240 of the span length, ensuring the durability and safety of users.

Material Thickness: The average thickness of mild steel grating is between 3/16" (4.8mm) and 1/4" (6.4mm), while aluminum grating is mostly 1/8" (3.2mm) to make the weight lighter. The stainless steel and other materials may have thicknesses defined for heavy-duty or corrosive environments.

Flatness and Warping Tolerance: The surfaces of the grating must be perfectly flat to eliminate the risk of tripping and enable even load distribution. The recommended thickness tolerance for flatness is ±0.125 inches by the industry guidelines.

Open Area Ratio: Drainage and ventilation are strongly influenced by the open area percentage in the grating. The typical open area ratios for different applications (e.g., pedestrian walkways vs. industrial platforms) range from 50% to 72%.

Anti-Slip Features: Treads and serrated surfaces are the most common ways of increasing grip. The specifications typically require that, in wet conditions, the slip-resistance coefficient would be at least 0.5.

Following the specifications and tolerances, companies guarantee their grating installations to be safe, have a long life and perform uniformly during different conditions.

Key Specifications for Steel Grating

In the process of choosing steel grating for different applications, a variety of specifications and data points are to be taken into account to guarantee the three aspects of functionality, safety and compliance with the standards of the industry. The specification and details listed below are for the steel grating of today’s time:

Load-Bearing Capacity: One of the features of steel grating is its ability to support the heavy loads of the various metals used in its construction. A case in point: the bar grating, made of carbon or stainless steel, usually has a load support capacity of 4.8 kN/m² to 14.4 kN/m², with the particular load span determined by bar size, spacing, and material grade. Industrial use or even vehicular applications might require heavy-duty products capable of handling even more weight.

Material Options:

Carbon Steel: This is the least expensive option and proper for the majority of general applications but it will not be rustproof without galvanization.

Stainless Steel: This has the greatest lifespan as it won’t rust; very tough and a good choice in places with chemicals or moisture.

Aluminum (optional): It is strong and rust-free but not as strong as grating made of steel.

Surface Treatment:

Rusting of steel grating is most frequently prevented by galvanization, which provides a zinc coating that prolongs the life of the metal.

Another option is powder coating for aesthetic appeal or extra protection.

Bar Spacing and Thickness:

The spacing criteria in the standard are from 19mm to 30mm on center for the bearing bars and 30mm to 100mm for the crossbars. Tight spacing helps attain strength while keeping debris penetration down, making this very common in pedestrian and ADA-compliant applications.

Bar thickness is typically from 3mm to 6mm yet is flexible depending on the load demands and the particular application.

Slip-Resistance Coefficient:

A major safety factor is that steel grating must undergo slip-resistance testing. According to industry standards, a slip-resistance coefficient of at least 0.5 in wet conditions and higher in dangerous environments is recommended. Using serrated surfaces is one way to improve grip.

Industry Compliance:

Steel grating should meet the requirements of such standards as ANSI/NAAMM MBG 531 for metal bar grating or BS 4592 for European compliance. Compliance with these standards guarantees the same quality, load-carrying capacity and safety across the board of applications.

Environmental Considerations:

Recycling and sustainability are getting increasingly important factors. Steel grating can be reprocessed up to 100%, making it an eco-friendly option for building and manufacturing.

The fusion of these specifications with the latest technologies and materials contributes to the developing of steel grating solutions that not only assure safety but also provide aesthetic flexibility and performance durability tailored to the diverse requirements.

Understanding Load Tables and Their Importance

Load tables are pivotal elements in the design and selection of steel grating systems. They give detailed data to engineers, architects, and designers about the different grating types’ load-bearing capacities, thus ensuring that the right product for the specific use is selected. The use of these tables makes it easy to determine the maximum load, the limits of deflection, and the span capabilities of installations which are therefore efficient and safe. The following are five crucial data points that are commonly found in load tables:

Type of Grating:

Indicates the material as well as the type of grating i.e., welded, press-locked, or swaged aluminum.

Span Length:

Specifies the distance between the supports and shows the maximum span allowed for load support.

Load Capacity:

Describes uniform and concentrated load capacities, thus confirming the grating's ability to withstand the expected forces.

Deflection:

Sets limits on how much the grating can bend under load, thereby protecting animal and human lives and the structure from damage.

Surface Finish:

Details treatments like galvanization or coatings which give the material resistance to corrosion and enhance its durability.

Technical analysis of these data points enables professionals to provide steel grating that is both safe and meets the project's requirements.

Tolerance Levels in Grating Manufacturing

Tolerance levels in grating manufacture are very important for dimensional stability, correct fit, and achieving the performance standards required in different applications. Tolerances are the primary guidelines for parameters such as bearing bar spacing, cross bar positioning, and the overall granulating size.

Bearing Bar Spacing Tolerance:

Bar spacing between bearings is one of those factors that has a maximum limit of ±2% of the original intended center-to-center distance. This step controls how loads are distributed and keeps the grating from collapsing under them.

Cross Bar Placement Tolerance:

For cross-bar placement, the allowed deviation is often ±1/8 inch (±3.2 mm), the minimum required for the connection to be firm and the support to be steady.

Panel Dimensions Tolerance:

The total width and length of the grating panels are specified with a tolerance of ±1/4 inch (±6.4 mm). Such a level of precision allows alignment and installation within the larger structure without any disturbance.

Flatness Tolerance:

The grating panels are to be flat to the thickness standards so they are secured and safe in their positions. A bow or deflection of the panel is often limited to a maximum of 1/4 inch over a 10-foot span.

Cut-Out Dimensions:

For custom configurations with cut-outs, a tolerance standard of ±1/16 inch (±1.6 mm) is usually used to avoid mismatches with the penetrations of pipes or structural components.

Twist Tolerance:

A limit of 2 degrees is the maximum twist usually allowed for any part of the grating, to prevent uneven surfaces that could become a safety hazard.

The quality assurance processes that the manufacturers have to implement are very strict in order to be able to comply with such tolerances and at the same time produce high-quality products that will be safe and up to the standards of the projects. These tolerances are similar to the global ones set by ISO 14122-2 and NAAMM MBG 531 which help to keep consistency and reliability.

The manufacturers have reached a point where they can produce gratings with tighter tolerances while also enabling greater customization. The use of modern production technology, precision machines, and automated quality control systems is the reason behind this. The manufacturer’s dedication to precision comes in the form of increased grating lifetime along with the guarantee of optimal performance even in challenging applications of various kinds.

Innovations in Steel Grating Design

Innovative solutions to improve durability, sustainability, and functionality have been introduced through recent advancements in steel grating design. The integration of high-strength materials, such as stainless steel alloys and galvanized coatings, is one of the most remarkable developments, significantly increasing resistance to corrosion and wear in harsh environments. Industry data shows that stainless steel grating with advanced coatings will survive 30% longer in corrosive conditions when compared to traditional materials meaning a lower long-term maintenance cost.

In addition, the application of advanced manufacturing techniques, such as laser cutting and 3D modeling, enables the creation of highly customized grating solutions. These technologies can come up with designs that will be used in different spots such as the case of drainage systems, walkways, and industrial platforms, thus giving numerous functional efficiency and aesthetic appeal. For example, modular grating designs are increasingly accepted for rapid installations, especially in industrial construction and marine operations.

Sustainability is another important aspect of steel grating design today. The industry consumes less energy and reduces its overall carbon footprint by making large use of recycled materials. In one recent report, it is estimated that the use of recycled steel in grating production can lead to the use of only 30% of the energy required to produce new steel which is in line with the global carbon neutrality goals.

Additionally, innovations in safety have advanced with the introduction of slip-resistant surface treatments and enhanced load-bearing capacities, among others, thereby making the grating more accessible in high-traffic or hazardous areas. One of such case applications is the provision of slip-resistant treads which have been credited with reducing workplace slips and falls in industrial settings by 25%. Compliance with strict global standards, such as ASTM A123 and OSHA requirements, is one of the reasons for continued improvements in worker safety.

All these innovations, combined, contribute to the evolution of steel grating design, making it more sustainable, safer, and performance-oriented in addressing contemporary infrastructure and industrial challenges.

Advancements in Fabrication Techniques

The manufacturing of steel grating has seen remarkable improvements in precision, cost-effectiveness, and versatility due to recent developments in related techniques. The application of a new method is cutting with laser technology that has reached the automated level. It not only allows for very precise, detailed designs but also minimizes material waste. According to industry reports, laser cutting can speed up production by 30% while enhancing product quality and consistency.

The history of innovation is also associated with the introduction of robotic welding systems, which have been considered a change in the assembly process. These systems have not only ensured weld uniformity but also increased production capacity by 40%, enabling them to cope with the increasing demand for customized steel grating. Besides, with computer-aided design (CAD) software, manufacturers can produce complex prototypes and finalize the most accurate designs quickly and easily.

Moreover, the least discussed yet most important factor in cutting the industry’s operational costs is adopting green practices, such as recycling scrap metal and using energy-efficient equipment, alongside the industry’s environmental goals. The use of advanced coatings, such as hot-dip galvanizing, provides enhanced corrosion resistance, increasing the lifespan of steel grating by 50% and is supported by recent studies.

All these innovations have collectively highlighted the cutting-edge aspects of fabrication techniques that have substantially raised the performance, durability, and even the sustainability of steel grating while aligning with the dynamic requirements of industrial and infrastructural projects globally.

Benefits of Serrated Surface Grating

Enhanced Slip Resistance

The serrated surface creates a rough and gripy surface which allows the user to have a firm and secure hold. The user does not need to be concerned about slippery conditions (wet or oily). Research shows that serrated grating can enhance slip resistance by 30% compared to the standard grating.

Improved Safety Standards

Serrated grating, which has a hard-to-slip surface, not only protects workers but also helps the facility meet the safety regulations and standards of that particular place, thereby creating a safer atmosphere for employees.

Better Load Distribution

The serrated grating allows the load to be more uniformly spread out than a plain grating and this ensures that there is no weakening of the structure even with heavy loads. This property makes it suitable for the industrial environment, where heavy machinery or large crowds are common.

Durability in Harsh Environments

The cutting-edge design not only improves the surface tolerance but also makes it more resistant to the extreme environmental conditions like very high or very low temperatures, corrosive environments, and physical wear.

Cost-Effectiveness

Serrated surface grating lasts long and requires very little maintenance, making it an economical choice with long-term savings on replacement and repair costs.

Emerging Trends in Welded and Riveted Grating

Sustainable Materials and Processes

The trend toward eco-friendly materials and manufacturing processes is rapidly on the rise. Gratings made from recycled metals and techniques that reduce waste and energy consumption are becoming increasingly popular, thereby supporting the worldwide drive for better environmental conditions.

Enhanced Anti-Slip Technology

New cutting-edge safety features are being applied to grating that is welded and riveted. Among the inventions are more complex serrated shapes and coatings that could be used as anti-slip surfaces, especially in industrial and wet environments where traction requirements are very high.

Lightweight but Strong Materials

New materials, including advanced alloys and composite metal hybrids, are being considered to achieve a lightweight grating without sacrificing strength and bearing capacity. This changeover is a response to demand for grunt-free installation and cost-efficient transportation.

Smart Grating with Sensors

The embrace of smart technologies has led to grating that features sensors integrated within it. Such sensors are capable of keeping the track of the health of the structure, spotting stress or corrosion, and sending real-time data for maintenance, thus increasing safety and efficiency in industrial applications.

Customizable Designs for Aesthetic and Functional Needs

Customization has been a key trend, with manufacturers offering custom-made grating designs that perfectly fit aesthetic or specific operational needs. This method allows industries to obtain grating solutions that not only meet functional requirements but also complement architectural styles.

Applications of Steel Grating in Various Industries

Steel grating is a material that offers durability, strength and flexibility and is therefore extensively used across many industries. The applications listed below are key in value and are examples of the use of steel grating in various industries:

Industrial Flooring

Steel grating is a typical flooring choice for industrial settings such as factories, warehouses, and manufacturing plants. The material can bear heavy loads and, at the same time, provide good ventilation and drainage, which are the primary reasons for its preference. Reports indicate that the design of steel grating has now been incorporated into 60% of the industrial flooring systems.

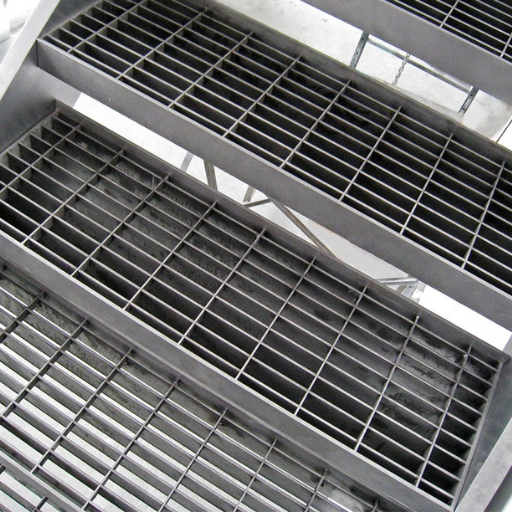

Stair Treads and Walkways

High-traffic areas around stair treads and walkways often use steel grating primarily for its slip-resistant surface and load-bearing capacity. This is a very important factor in safety-conscious environments such as construction sites and offshore platforms.

Drain Covers and Trench Covers

Urban drainage systems often use steel grating for trenching and cover. Its lightness, combined with its toughness, allows maintenance to be carried out without interrupting traffic of cars and pedestrians.

Mining and Energy Sectors

In these sectors, steel grating is a must. It is used to make platforms, floors, and safety barriers in mining and energy production. Its tensile strength is so high that it can be relied upon in extreme situations like those found in mining shafts or oil rigs.

Transportation and Public Infrastructure

Bridges, overpasses, and public transport systems incorporate steel grating for pedestrian walkways, ventilation grilles, and structural reinforcement. Its flexibility and long lifespan make it indispensable for large municipal and highly circulated infrastructure.

Industrial Applications of Steel Bar Grating

Steel bar grating is very durable and strong, requiring low maintenance, making it a versatile and reliable solution for a variety of industrial applications. This text presents five major industrial applications for steel bar grating:

Chemical Processing Plants

The steel bar grating flooring is made of a material that withstands both chemical exposure and high temperatures, making it ideal for flooring, platforms, and walkways in chemical processing facilities. Its open design is also coupled with ventilation and drainage, thus ensuring safety and cleanliness in these demanding environments.

Power Plants and Energy Facilities

Steel bar grating is the main choice for power generation facilities where maintenance walkway platforms, ventilation covers, and stair treads are used. In such critical settings, the material's heavy load-bearing properties, along with exposure to heat and moisture, ensure continuous operation without failure.

Oil and Gas Industry

Durable materials such as steel bar grating are required for the construction of walkways and safety barriers on offshore platforms and drilling rigs. The material’s slip resistance and high weight tolerance are essential for worker safety in dangerous, high-pressure situations.

Automotive Manufacturing

The assembly lines and production floors are equipped with steel bar grating due to its strength and open structure. Heavy machines are thus supported along with efficient drainage and airflow, and safety and operational efficiency are optimized.

Food and Beverage Processing

Food and beverage establishments need hygienic and easy-to-clean flooring options. The bar grating from steel meets these standards as it is resistant to corrosion and also contributes to the proper drainage, thus preventing contamination and maintaining compliance with health regulations.

Using Grating in Architectural Designs

Steel bar grating is not just a practical solution but it is also very flexible and even an element of style in the whole architecture. Different uses of grating in architecture are discussed below.

Facades and Cladding

Steel bar grating can be used as a facade to completely transform a building's look in a very attractive way. The open-grid design lets in more air and light while keeping the interior modern and industrial-looking. Being durable and weather-resistant, these characteristics also help reduce maintenance expenses for a very long time.

Sunshades and Louvers

Grating is an efficient material for making sunshades and louvers, which use less power and wear and tear on architects because they primarily construct elements that are very effective at reducing heat gain. Filtering of the sunlight improves the building's climate control, adds a soft touch of the building's overall appearance, and increases the energy efficiency.

Walkways and Catwalks

Grating is more than a material for walkways and catwalks in urban-style architectural spaces like rooftop gardens or elevated floors. These structures are very strong, but they also provide a slip-resistant surface that is safe and so, they do not compromise on weight and do not look bulky.

Staircases and Railings

Steel grating staircases and railings are a perfect combination of safety and style. The open design prevents water and debris from building up, thus providing good traction in Inclement weather. Their sleek, industrial look is often chosen as the preferred one in contemporary design applications.

Landscaping Elements

Grating is a perfect tool in landscaping, as it not only serves its purpose but also integrates beautifully into the outdoor spaces. For instance, it is used for tree grates, drainage covers, or decorative platforms that skillfully combine functionality with creativity to transform public spaces and urban landscapes.

Grating as a Safety Feature in Construction

Grating is one of the most important safety features used on construction sites, as it is impossible to prevent slips, trips, and falls in danger zones without it. To me, the whole design creates a scenario where people can safely ascend and descend stairs or walk through any part of the site, thereby reducing the risk of accidents. What's more, it improves not only the light but also the water drainage and these two factors are the most crucial ones for the safety of the staff on the construction site.

Frequently Asked Questions (FAQ)

What is steel grating design and its applications?

Steel grating design involves the fabrication and specification of grating panels from metal, such as steel or aluminum, which are used in various commercial and industrial sectors. In addition to such applications, they can also be used for walkways, mezzanines, and catwalks because they are strong and resistant to slipping, with an advantageous strength-to-weight ratio, making them capable of bearing heavy loads.

How is stainless steel grating different from traditional grating?

While traditional grating is made of mild steel and is either galvanized or painted, stainless steel grating is made of stainless steel, which offers corrosion resistance and thus provides a cutting advantage in non-corrosive environments. In short, it is the most suitable choice for corrosion-prone areas like chemical factories and water treatment plants, leading to applications such as industrial flooring and architecture for a long time.

What are the benefits of using welded bar grating?

Welded bar grating consists of a stronger and more stable construction when compared to other grating types due to the nature of the bonding operation in which cross bars and bearing bars are welded together. This construction further increases the structure's robustness and efficient loading area, making it suitable for heavy-duty applications such as industrial plants and infrastructure.

What is the significance of bearing bar spacing in steel grating?

Bearing bar spacing is vital in the designing of steel grating as it specifies the capacity of the grating to hold weight and the overall sturdiness of the grating. When the spacing is right, the grating can provide maximum support for heavy loads while at the same time ensuring safety and functionality in grating applications like walkways and trench covers where pedestrian traffic is most common.

How do I select the right metal bar grating for my project?

Choosing the appropriate metal bar grating requires considering load requirements, material type (steel or aluminum), and the design specifics of your project. One should also pay attention to the tolerance levels, cross bar spacing as well as the environment where the grating will be installed in order to achieve the best performance.

What are the ADA requirements for steel grating?

The Americans with Disabilities Act (ADA) has established accessibility standards for public places, and steel grating is one factor influencing compliance with these guidelines. The grating must be secure and robust, and its openings should be large enough to allow pedestrians to pass easily without exposing them to dangers such as stumbling on the grating's topography; thus, all people, regardless of mobility limitations, can move through walkways and other areas with ease.

Can aluminum grating be used for heavy-duty applications?

Aluminum grating is less sturdy than steel grating but in terms of heavy-duty applications, it can still be subjected to designing if it matches the strength requirements. Moreover, aluminum's corrosion resistance allows its use in areas where steel may not be suitable. Nevertheless, one should consult the appropriate engineering and load tables to ensure safety.

What types of grating solutions are available for industrial flooring?

Welded, pressure-locked, and riveted grating are all options for industrial flooring. Each grating type offers distinct benefits in load capacity, slip resistance, and installation methods, allowing users to choose the most appropriate solution for their specific application and design requirements.

How do grating supports influence the design of grating panels?

Support for grating significantly impacts the designing and securing of grating panels. They ensure the grating is firmly fixed, so it can withstand heavy loads and provide adequate support. Moreover, well-designed supports also help keep the grating in its correct position, thereby increasing safety and efficiency across different applications.

Recently Posted

-

Aluminum Steel Grating: A Comprehensive Guide to Grating Products

December 23, 2025In industrial flooring applications, safety, durability, and versatility are the most essential characteristics. Among materials, Read More

Read More -

Understanding 316L Stainless Steel Bar Grating: Properties, Applications, and Advantages

December 22, 2025The 316L stainless steel bar grating is the material most people choose when applications are challenging and require high perform Read More

Read More -

Essential Steps and Tools for Building a Fence: A Complete Guide

December 19, 2025No matter the reason, outdoor areas that are more private, secure, or simply well-delineated, a fence will certainly be a very nic Read More

Read More -

Metal Fencing Options: Choosing the Right Type of Metal Fence

December 18, 2025Metal fences do not only serve as barriers but also as a mixture of functionality, durability, and style that can change any prope Read More

Read More