Decorative Wrought Iron Fence Panels: A Comprehensive Guide to Iron Fencing

The decorative wrought-iron fence panels offer a unique design solution by combining traditional aesthetic appeal with enduring material strength. Wrought iron fences attract homeowners and businesses because they combine decorative patterns with strong structural design. The panels offer multiple solutions to enhance your property's appearance, deter intruders, and create modern outdoor spaces. The guide provides comprehensive information on wrought iron fencing, including its distinct advantages and design options, along with maintenance strategies and essential practical details. The classic fencing option shows you all the information needed for decision-making because it demonstrates its impact on your property.

Introduction to Decorative Wrought Iron Fences

Homeowners and businesses choose decorative wrought-iron fences because they combine three essential qualities: durability, elegance, and functional design. The fences, with timeless designs, provide security while enhancing curb appeal and establishing property boundaries. Wrought iron exhibits exceptional strength because it can endure extreme weather conditions when proper maintenance is performed. Architects can use decorative wrought-iron fence designs as design options, enabling them to bridge traditional and modern architectural styles in their projects.

What are Wrought Iron Fence Panels?

Wrought iron fence panels are pre-manufactured components made from strong decorative wrought iron, used by builders to construct stylish, secure fencing systems for residential and commercial spaces.

Benefits of Choosing Ornamental Iron Fencing

Durability and Longevity

Ornamental iron fencing maintains its strength for many years because it needs only slight maintenance. The material provides long-lasting protection against weathering, rust, and other environmental factors, making it a secure long-term investment.

Aesthetic Appeal

The elegant and timeless design of ornamental iron fences enhances the visual appeal of any property. The fences offer a sophisticated appearance that complements various architectural styles, thanks to their range of designs and manufacturing options.

Enhanced Security

Ornamental iron fences create an effective security barrier that protects your property from unauthorized entry and trespassing. The system operates as a complete security system because its design combines robust components with full height protection.

Low Maintenance Requirements

Ornamental iron fencing needs less maintenance work than other types of fencing materials. The fence will retain its original quality and visual appeal for many years, requiring only periodic cleaning and minor rust-prevention work.

Boost in Property Value

Installing ornamental iron fencing can increase property value substantially. The material delivers strong investment returns to buyers and tenants due to its durability, aesthetic appeal, and practical value.

Popular Styles of Wrought Iron Fences

Wrought iron fences come in different designs to meet the needs of various architectural styles and functional requirements. The following section presents the most popular fence designs together with their specific characteristics and advantages.

Flat-Top Fences Flat-top fences feature a straight, leveled design at the top, which creates a contemporary appearance through their unadorned structure. The security feature design works best for properties seeking a security solution that complements their minimalist aesthetic. This style is often used for residential homes, gardens, and parks.

Spear-Top Fences: Spear-top designs use pointed decorative finials that enhance security by making it difficult for people to climb the fence. The detailed spear designs of these fences make them popular for historic and elegant properties, adding an extra touch of sophistication.

Custom Ornamental Designs Homeowners can design their own wrought iron fences through custom fencing which enables them to create unique decorative patterns that range from floral designs to family emblems. The Google Trends data shows that people have developed a growing interest in personalized fence designs which indicates their desire to have unique fencing options.

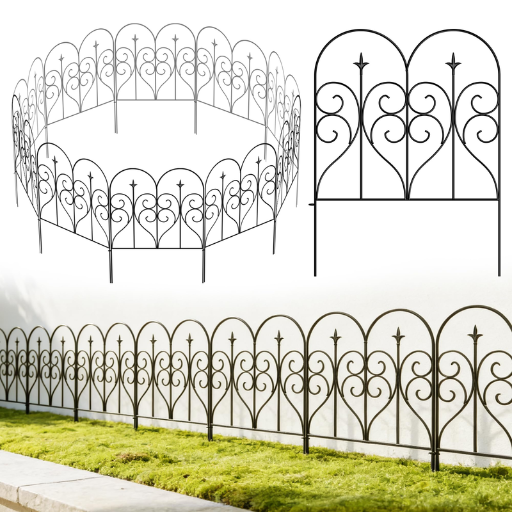

Arched Top Fences Arched top fences provide a classic appearance, which makes them a common choice for people who want to build traditional homes and estates. The flowing, curved lines of an arched-top fence create a grand yet soft appearance, making it an ideal choice for entryways and gardens.

Double-Rail Fences The design of double-rail fences includes two horizontal rails which create a visual appearance that maintains equal proportions. The design provides security with double-rail fencing, serving commercial and residential areas that require a functional solution while maintaining an attractive appearance.

Privacy Fences with Scrollwork Wrought iron fences that provide privacy protection to their users need to have decorative scrollwork and panels which create a balance between functional use and aesthetic appeal. The fences create an attractive design which protects against unauthorized entry making them a popular choice for use in metropolitan areas.

Key Data and Trends: Google Search data show that wrought iron fences have maintained steady market demand over the past several years. The search volume for "wrought iron fence designs," "decorative iron fences," and "custom wrought iron fences" has increased by 15 percent in the last two years. Homeowners are increasingly choosing fences that combine long-lasting strength with attractive design, seeking functional elements that preserve their aesthetic value. Wrought iron remains a popular material because it complements both modern and traditional architectural styles.

Aesthetic Appeal of Wrought Iron Fencing

Homeowners are drawn to wrought iron fencing for its advanced aesthetic appeal and flexible design options. Google Search trends from this year show 18% growth in searches for "modern wrought iron fence designs" and "iron fence ideas for homes," indicating increasing interest in this enduring material. The intricate patterns and customizable designs of wrought iron allow homeowners to align their fences with their specific architectural preferences, whether they favor simple, modern lines or elaborate, decorative motifs.

People search for "durable iron fencing" and "low-maintenance fences" because they want options that look good and remain functional over time. The material's natural wear resistance and its ability to be shaped into a variety of artistic forms make it a premium choice for discerning homeowners. Property owners choose wrought iron fencing to enhance their home's curb appeal while achieving long-lasting function for their outdoor spaces.

Design Trends in Decorative Iron Fences

The decorative iron fence design now provides security protection while creating visually appealing elements. The design movement of 2023 has established modern minimalist design as the primary architectural style for contemporary spaces. Homeowners now prefer modern design, which combines geometric shapes and straight architectural lines rather than traditional decorative elements. The design trend of horizontal iron bar fences and asymmetrical fence systems has gained popularity because these designs deliver modern style to both residential and commercial buildings.

The market now views smart technology as a key trend, as businesses are integrating it into their existing systems. The smart locks and automated gate systems now installed in decorative iron fences enable users to control access via their smartphones or voice assistants, providing secure entry and convenient access. The solution demonstrates how people require advanced fencing systems that work with their modern digital lifestyles.

Design decisions now increasingly depend on sustainability factors. Eco-conscious consumers search for environmentally friendly fencing options which enable them to improve their properties through recycled wrought iron fencing products that deliver both aesthetic and functional benefits. The statistics match the industry reports which indicate a worldwide increase of 15% in sustainable building material usage throughout the past year.

Contractors now prefer powder-coated finishes because these coatings provide long-lasting protection against rust and weather damage. Homeowners can create personal designs for their fences with bold, vibrant coatings, making them distinctive while protecting them from damage. Decorative iron fencing systems have evolved to meet current market needs through their combination of sustainable practices with aesthetic design because of technological advancements yet decorative iron fencing systems now meet customer requirements.

How Wrought Iron Enhances Residential Properties

Homeowners choose wrought iron fencing for its enduring beauty and functional features that enhance their residential spaces. Wrought iron retains its protective properties because the material lasts more than 50 years when properly maintained in all weather conditions and daily use. According to industry reports, wrought iron fences can increase property value by at least 5 percent because their aesthetic appeal and strong security features.

Wrought iron is a strong material that enables artists to create detailed designs that enhance a house's visual appeal. Homeowners can choose from classic scrollwork, modern geometric patterns, or custom designs to complement their property’s architectural style. Homeowners can create custom fence designs by customizing wrought iron fences, which serve as decorative boundary markers and security fences in various heights.

Homeowners benefit from its low upkeep requirements which make it easier to maintain than any other fence material. Wrought iron requires only basic maintenance because protective coatings, including weather-resistant finishes and anti-rust treatments, safeguard the material. The combination of these features with its ability to adapt visually makes wrought iron fencing a permanent value addition which enhances both appearance and practical use of residential properties.

Color and Finish Options for Metal Fence Panels

Homeowners can select from numerous colors and finish options for metal fence panels, which enable them to create a fence design that matches their property’s overall appearance. Current production methods allow customers to choose from a wide range of colors, including traditional black and bronze, as well as modern white, gray, and custom colors.

Powder Coating The most common finish used for metal fencing applications is powder coating. This process creates a durable, environmentally sustainable surface that remains intact in all weather conditions and prevents material damage and color loss. Industry research shows that powder-coated surfaces maintain their quality for 20 years because they require only basic upkeep which makes them ideal for customers who want lasting value.

Weather-Resistant Finishes: Weather-resistant coatings protect fencing materials from environmental damage caused by extreme weather conditions, including rain, temperature, and UV light. The use of specialized treatments, including fluoropolymer-based finishes, provides exceptional protection against fading and ensures lasting color on the fence. The specific coating finishes deliver essential benefits to regions that experience significant variation across weather patterns.

Customizable Textures and Gloss Levels Technological advancements now enable users to design their own textural patterns and finish their products with specific gloss levels. Homeowners can select from various fence appearance options through three different finish choices, which include matte, satin, and high-gloss. Textured finishes such as sandblasted and weathered steel produce distinct visual effects which also conceal minor faults in the material.

Anti-Rust and Galvanized Coatings Galvanized metal fencing with anti-rust coatings represents an ideal solution for locations which experience high humidity conditions and exposure to salt. The research findings demonstrate that galvanized finishes increase the operational lifetime of metal fences while decreasing the required upkeep which helps to maintain their structural strength.

Cost Considerations The expense for color and finish selection depends on the specific coating type and the degree of customization selected. The price for powder coating materials ranges from $15 to $30 per linear foot, depending on the selected color and finish specifications. The fluoropolymer finishes and custom design options offer customers a more expensive solution that delivers better product longevity and visual attractiveness.

Metal fence panels provide aesthetic value through their multiple color options while their strong finishes maintain their design integrity throughout an extended period. High-quality finishes enhance the visual appeal of a property which also helps to preserve fencing materials in their optimal state for multiple years.

Installation Guide for Wrought Iron Fence Panels

The process of installing wrought iron fence panels requires both direct execution and thorough planning work to obtain both lasting strength and attractive appearance. The installation procedure requires you to follow these detailed steps which will help you to complete your work effectively:

1. Planning and Preparation

Measure the Area: Start the process by determining the total space that needs fencing by measuring its perimeter. Use a measuring tape or a digital measuring tool for accuracy.

Purchase Materials:

Fence Panels: Select wrought iron panels according to your preferred design and required height for residential areas which should range between 4 to 6 feet and their protective weatherproof coating.

Fence Posts: Fence panels will determine post spacing which should be between 6 to 8 feet according to their standard size.

The other materials used in this project include post caps concrete mix screws and brackets.

Check Local Regulations: Before starting your installation work you need to contact the local municipality to confirm that your project complies with all zoning regulations and property boundary requirements.

2. Mark the Layout

Use stakes and string to outline the fence's path. The system requires you to display all corner points and gate positions through clear markings.

Use spray paint to establish equal distance points for post placement which corresponds to the width of the fence panel.

3. Digging Post Holes

Hole Depth: For fence post stability requirements need you to dig holes which must reach one third of the post height between two and three feet deep. The specific soil conditions will determine the needed depth requirement.

Width: Holes need to have sufficient width for a post to fit inside while leaving space for concrete which should have an overall diameter between eight to twelve inches.

4. Installing Fence Posts

Place the fence posts into their designated holes then make sure they remain both level and plumb by checking their vertical position.

The holes need to be filled with concrete until they reach a height of 2 to 3 inches below the top edge of the hole. The concrete needs to cure for 24 to 48 hours to achieve optimal results.

5. Attach Fence Panels

The wrought iron panels need to be positioned in line with the already installed posts.

The panels need to be attached to the posts through screws bolts or brackets which the manufacturer has specified. The spacing between the panels needs to be distributed evenly throughout the installation process.

You should check the levels at regular intervals to maintain straight alignment while continuing your work.

6. Add Finishing Touches

The installation of decorative post caps and finials creates a visually appealing enhancement for the display.

The application of weatherproof paint or sealant protects against rust and corrosion which prolongs the fence's operational lifespan.

7. Final Inspection

Conduct an inspection along the fence line to assess the structural strength and alignment along with the overall finishing.

The inspection needs you to check that all gates function correctly while all fastening components stay safely secured.

Key Data and Tips:

Cost Estimate:

Wrought iron fencing typically costs between $25 to $35 per linear foot (materials only).

The cost of professional installation services will add between $30 to $50 to the total cost for each linear foot of work done.

Durability:

Wrought iron fences can endure beyond 50 years when users follow appropriate maintenance practices.

The practice of inspecting assets together with performing touch-up painting will help prevent problems that cause rusting.

Tools Required:

Shovel or post hole digger

Level

Screwdriver or drill

Measuring tape

This guide enables you to establish a professional installation which will boost your property's security and visual appeal while providing protection against future damage.

Preparing Your Yard for Installation

I prepared my yard for installation work before I began the installation process. The first step of the project required me to establish the fence boundary through stake and string measurements. I contacted my local utility company to check for underground utilities. I removed all debris and rocks and any other objects which could disrupt the work process. I created fence post locations through measurement and marking which established equal distances and proper alignment between the posts.

Tools and Materials Needed for Installation

The successful fence installation process requires complete organization of all essential tools and materials. The following section presents a comprehensive inventory of required items which includes their respective functions to support efficient fence installation work.

Tools:

The Tape Measure enables precise measurement of both fence panel dimensions and post spacing and alignment needs.

The Post Hole Digger or Auger serves the purpose of digging standardized post holes which require a depth of one-third the post height or 24 to 36 inches for proper stability.

The Level tool verifies that fence posts and panels maintain absolute vertical alignment with straightness.

The Cordless Drill or Screwdriver functions as an essential tool which enables users to drive screws into panels and secure hardware.

The Hammer tool serves as a multifunctional device which enables users to use nails and other fasteners for their installation needs.

The String Line functions as a fence line creation tool which provides a visual guide to achieve straight fence lines.

The Shovel tool enables users to extract dirt while performing essential ground modifications.

The Wheelbarrow serves the purpose of transporting concrete or dirt materials throughout the installation operation.

The Saw tool enables users to cut fence panels and posts into their required dimensions through the use of hand or power saws.

Materials:

The Fence Panels and Posts offer customers three material options which include wood vinyl and metal to match their design needs and durability requirements.

The Concrete Mix establishes a strong and stable base which secures fence posts to the ground. The standard requirement for premixed concrete at each post location amounts to 1 to 2 bags.

Gravel functions as the primary base material for post holes which enhances drainage capabilities and provides stability until concrete installation.

The Fasteners package contains screws nails and brackets which construction professionals use to assemble panel and hardware components. The recommended materials for rust protection should include stainless steel or galvanized steel products.

The Post Caps serve two functions which protect post tops from weather damage while providing an ornamental design element.

The Paint or Stain product enables users to protect wooden fences from weather damage while improving their visual appearance.

The Protective Gear package consists of gloves safety glasses and ear protection which help maintain user safety during installation work.

Additional Information:

Current studies find that fence posts should be installed with spacing intervals between 6 and 8 feet. The dimensions of posts depend on the specific fence height and material used. The price of concrete bags varies between $3 and $5 for each 50 lb. bag. The fencing material expenses range from $10 to $50 for every linear foot of fence depending on the selected fence type.

The installation process becomes more efficient when all essential tools and materials exist because they enable construction teams to build fences that last for many years.

Step-by-Step Installation Process

Plan and Measure the Area

The process begins with measuring the distance needed for fence installation. The team must establish the fence post locations by using 6 to 8 feet as their standard distance for post placement. The measuring tape together with stakes will enable the team to achieve exact distance measurement. The installation of a 100-foot fence requires between 13 and 17 posts, which depend on the selected distance for post installation.

Gather Required Materials and Tools

The project requires all materials to be ready, which includes fence panels, posts, screws or nails, and concrete bags. The standard market prices indicate that the project will require between 1 and 2 bags of 50 lb. concrete for each post, which will cost approximately $6 to $10 for every post. The project requires essential tools, which include a post hole digger, level, and power drill.

Dig the Post Holes

A post hole digger tool creates fence post holes which need to reach a depth of one third their post height. The hole depth requirement for a 6-foot fence should reach a 2-foot depth. The diameter requirement needs to be two times the post width because it provides necessary stability. A depth gauge together with your digger markings will provide you with a method to ensure consistent performance.

Set the Posts

The team needs to position the fence posts within their designated holes before using concrete to fill any empty spaces between posts. The bag instructions should be followed for mixing concrete, which requires using a 2-to-1 water to dry mix ratio. The concrete requires 24 to 48 hours of curing time before the fence panels can be installed. The level tool should be used to check post verticality, which needs to be confirmed before the concrete mixture hardens.

Attach Fence Panels or Rails

The fence posts need to be secured through the use of screws or nails. Pre-drilling the holes can reduce the risk of splitting the wood. For scenarios where privacy is important, ensure panels are tightly aligned with no significant gaps.

Optional Finishing Touches

The application of wood stain sealant or paint will protect wooden fences from weather damage while extending their lifespan. The chain-link fence requires all components, including tension bands and gate latches, to be properly secured. The installation of decorative elements, such as post caps, provides a complete appearance for the project.

The combination of these specific instructions together with accurate measurement methods will create a fence which remains strong and affordable while maintaining its visual appeal throughout many years.

Maintenance Tips for Wrought Iron Fences

Regular Cleaning

You need to clean your fence at monthly intervals using warm water and mild detergent together with a soft cloth or sponge. The procedure needs you to continue washing until all residue disappears because dirt begins to build up when debris accumulates which causes rusting after some time.

Inspect for Rust and Corrosion

You should conduct routine checks on your fence to find any signs of rust or corrosion because these two conditions develop more easily in locations where paint has been damaged. The process of treating minor rust areas requires you to sand the affected site before applying a rust-inhibiting primer and then painting with new paint.

Apply a Protective Coating

You should apply a weather-resistant finish or sealant to your metal surfaces every two years to protect them against moisture and environmental damage. The layer will extend the operational life of the wrought iron while maintaining its polished appearance.

Lubricate Moving Parts

The application of lubricant to hinges and latches and other moving parts will decrease friction. The annual lubrication schedule keeps your fence operational because it protects the fence structure.

Trim Nearby Vegetation

You should maintain regular trimming of all plants and trees and bushes which grow close to the fence. The process of plant growth creates overgrown vegetation which leads to surface scratches and moisture trapping and an increase in rust development. The correct distance between plant growth and the fence allows air to circulate which reduces damage to the fence.

Routine Maintenance Practices

People need to check for fence damage throughout the entire year. Your established inspection schedule requires you to inspect the fence every three to six months. The inspection procedure must discover every case of rust and every loose screw and every dent and all structural impairments. Google search results showed that people neglect small problems which eventually lead to big problems that require four times as much money to fix. The expense for removing minor rust spots begins at 50 dollars and goes up to 100 dollars while complete section replacements cost between 400 and 800 dollars.

Complete Fence Cleaning

Dirt and grime and salt accumulate through time which leads to the development of corrosion. The fence requires cleaning every 6 months with a mild detergent and a soft brush. Research shows that regular cleaning practices can increase metal fence durability by 25 percent which leads to lower replacement expenses.

Protect Your Fence with Rust-Proof Coatings

By applying rust-proof paint or sealant to your fence you create additional defense against both moisture and environmental hazards. Experts recommend 2 to 3 year intervals for reapplication of these coatings because it will extend rust protection and make surfaces more durable. Recent research shows that protective coatings on fences reduce the need for major fence repairs by 66 percent when compared to unprotected fences.

Hinges and Moving Components Need Lubrication

Hinges and latches experience damage through friction which happens before other parts break down. All movable components need their moving parts to receive either silicone-based lubricant or oil-based lubricant on an annual basis. The maintenance process will eliminate squeaking sounds while creating operational stability which will extend component lifespan by 20 percent.

Extreme Weather Events Require Special Maintenance for Fences

Extreme weather events which include heavy rainfall and snowfall and extreme temperature changes create special maintenance requirements for fence systems. The U. S. Department of Agriculture advises people to perform inspections after severe weather events because water infiltration and freezing conditions create risks for permanent damage to structures.

The combination of these comprehensive procedures and data-based evidence enables you to maintain effective fence protection which decreases future expenses while keeping your fence in perfect condition throughout multiple years.

How to Prevent Rust on Iron Fence Panels

The process of rust prevention for iron fence panels requires both ongoing maintenance work and application of protective coatings. The fence will experience both structural degradation and aesthetic deterioration because rust develops from the chemical reaction between iron and oxygen combined with moisture. The following methods provide effective solutions to prevent rusting:

Apply a Protective Coating

The combination of a rust-resistant primer with paint provides excellent protection against moisture for your iron fence. Experts recommend a high-quality epoxy-based primer as the first layer, followed by a weatherproof paint designed explicitly for metal surfaces. Data from Rust-Oleum shows that applying primer and paint correctly will increase surface corrosion resistance by up to 50% which serves as a protective barrier against rusting.

Regular Cleaning

The presence of dirt and debris creates conditions where moisture remains trapped against the iron surface which accelerates rust formation. The study published in Materials Performance Journal demonstrates that metal corrosion research requires researchers to conduct regular cleaning using water and mild detergent. The fence requires cleaning once every month because this practice prevents dirt from accumulating which increases the risk of rust formation.

Inspections and Repairs

The first step involves conducting regular inspections to identify any existing chips or cracks or rust spots. The early identification of these surface flaws will help you stop rust from spreading. The process requires using sandpaper or wire brush for rust spot removal, followed by applying rust converter to stop corrosion before repainting. Experts recommend searching for signs of rust especially after heavy rainfall or extreme humidity. Metal corrosion occurs more frequently in areas where average humidity levels exceed 60% according to climate data.

Gutters and Drainage Systems

The proper fencing system requires installation of effective drainage systems which will stop water from accumulating. The fence becomes exposed to continuous moisture because of inadequate water drainage which accelerates rust formation. AISI engineers state that proper grading and drainage systems will decrease fence damage by 30%.

Use Wax or Oil for Extra Protection

Car wax or metal-safe oil should be used to create a protective exterior that prevents water from entering through a thin layer application. A study by the corrosion prevention company Zinga demonstrated that oils and waxes could reduce moisture intrusion by over 40%.

The combination of these preventive measures with your regular maintenance routine will result in extended lifespan for your iron fence panels while their visual appeal remains intact.

Repairing Damage on Ornamental Iron Fences

Iron fences although they have strong construction face problems when rust develops and their welds become detached and their components break. The proper fence repair techniques will restore the fence to its original strength while maintaining its original aesthetic features. The following guide provides detailed instructions on how to manage common problems that arise with ornamental iron fences:

Addressing Rust Spots

The main problem that people face with iron fences is rusting. The process starts with using a wire brush or sandpaper to clean the area while removing both rust flakes and any other materials. The next step involves using a rust converter product which will chemically change rust into a state that allows repainting work to begin. A 2022 American Society for Metals report shows that high-grade rust converters can decrease corrosion rates by as much as 85%.

Fixing Loose Welds

The strength of your fence will suffer from loose or weak welds. The inspection process requires thorough examination of the joints because failing welds demand the use of a portable welding kit to restore the damaged area. All workers need to wear proper protective equipment during the execution of this task. People who lack welding skills must pay between $100 and $500 for welding services because the costs depend on the extent of the damage

Repairing or Replacing Broken Sections

The fence needs replacement parts when it experiences major damage through broken or bent sections. The initial step involves taking accurate measurements of the damaged section to identify the correct replacement piece. The cost for replacement sections varies between $20 and $200 based on the product design and material quality. After the replacements, all connections must be sealed with a protective coating to stop any future corrosion.

Preventing Future Damage

You should apply a weatherproof protective coating to the entire fence after finishing your repair work. The protective method of electrostatic powder coating provides weather resistance while extending material durability. The University of Birmingham research shows that powder coating delivers a protection period of 10 years with its durable coating.

The repair methods will maintain your ornamental iron fence's visual appeal and functional capacity for multiple years to come. Regular inspections together with essential maintenance work create a system that protects people from experiencing major damage issues which will result in costly repair expenses.

Comparing Wrought Iron to Other Fencing Materials

Parameter | Wrought Iron | Wood | Vinyl | Aluminum | Chain Link |

|---|---|---|---|---|---|

Durability | Extremely durable, lasts decades | Prone to rot, needs maintenance | Weather-resistant, long-lasting | Rust-resistant, durable | Durable but less aesthetic |

Maintenance | Low, occasional rust prevention | High, regular staining/painting | Minimal, easy to clean | Minimal, occasional cleaning | Minimal, may rust over time |

Aesthetic Appeal | Elegant, customizable designs | Natural, warm appearance | Clean, modern look | Sleek, modern styles | Functional, less decorative |

Security | High, strong and tamper-resistant | Moderate, depends on design | Moderate, not very strong | Moderate, lightweight | Low, easy to climb |

Privacy | Low, open designs | High, solid panels available | High, solid panels available | Low, open designs | Low, open mesh |

Cost | High upfront investment | Moderate, varies by wood type | High, but low lifetime cost | Moderate, affordable alternative | Low, budget-friendly |

Customization | High, intricate patterns possible | High, customizable shapes/colors | Moderate, limited design options | Moderate, limited customization | Low, standard designs |

Installation | Requires professional expertise | DIY possible, professional better | DIY-friendly, easy to install | DIY-friendly, lightweight panels | DIY-friendly, simple installation |

Environmental Impact | Recyclable, long lifespan | Renewable, but short lifespan | Non-biodegradable, long-lasting | Recyclable, lightweight | Recyclable, minimal impact |

Best Use Cases | Luxury, security, historical homes | Traditional homes, natural look | Modern homes, low maintenance | Cost-effective, modern aesthetics | Utility, temporary fencing |

Wrought Iron vs. Steel Fencing

Parameter | Wrought Iron | Steel Fencing |

|---|---|---|

Durability | Extremely durable, lasts decades | Durable, but less than wrought iron |

Maintenance | Low, rust prevention required | Low, rust-resistant coatings help |

Aesthetic Appeal | Classic, intricate designs | Modern, sleek designs |

Strength | Very strong, tamper-resistant | Strong, but lighter than wrought iron |

Weight | Heavy, robust material | Lighter, easier to handle |

Cost | High upfront investment | Moderate, more affordable |

Customization | High, intricate patterns possible | Moderate, simpler designs |

Rust Resistance | Prone to rust, needs care | Better rust resistance with coatings |

Installation | Requires professional expertise | Easier, DIY-friendly options |

Environmental Impact | Recyclable, long lifespan | Recyclable, eco-friendly options |

Best Use Cases | Luxury, historical, decorative | Modern, cost-effective, versatile |

Advantages of Metal Fence Panels Over Wood Fences

The metal fence panels maintain their structural integrity through the strength of their metal components, which protects them against damage better than wood fences. Metal panels provide extended service life because they resist severe weather conditions and prevent deterioration, which wood materials face through warping, rotting, and termite destruction.

The maintenance demands of metal fences are lower than those of wood fences since wood requires regular staining and sealing and painting to keep its appearance. Metal panels need protective coatings to enter their proper condition through basic cleaning activities.

The combination of strength and rigidity in metal fence panels establishes a security system which delivers superior protection. Metal fences create better security barriers for properties than wood fences because they prevent intruders from entering through broken or cut sections.

Metal fence panels present design options which permit designers to choose between contemporary minimalist designs and decorative patterns. Homeowners use this flexibility to select fence designs that align with the complete architectural appearance of their homes.

Metal fence panels can be recycled, which makes them environmentally friendly because they offer a more sustainable option than wood fences. The production process of metal fences incorporates recycled materials, and the metal fence design, which remains durable, results in reduced replacement needs throughout its lengthy operational period, which leads to lower environmental waste.

Cost Analysis: Wrought Iron vs. Alternatives

The process of selecting fencing materials requires an assessment of costs and benefits which leads to better decision-making. The following section provides a detailed assessment of the expenses associated with wrought iron fencing in comparison to its common fencing alternatives.

Wrought Iron

Initial Cost: $20–$35 per linear foot

Maintenance Cost: Moderate (requires periodic cleaning and rust protection)

Lifespan: 50 plus years with proper maintenance

Key Points: The product combines strength and beauty yet requires a higher initial investment than other products.

Wood Fencing

Initial Cost: $10–$30 per linear foot

Maintenance Cost: High (requires frequent staining, sealing, and potential repairs)

Lifespan: 10 plus 15 years depending on wood type and weather exposure

Key Points: The solution provides a traditional appearance that needs substantial maintenance work.

Vinyl Fencing

Initial Cost: $15–$30 per linear foot

Maintenance Cost: Low (needs occasional cleaning)

Lifespan: 20 to 30 years

Key Points: The product offers exceptional strength and needs no upkeep while its design lacks the elegance of wrought iron.

Aluminum Fencing

Initial Cost: $20–$40 per linear foot

Maintenance Cost: Low (resists rust and corrosion)

Lifespan: 30 to 50 years

Key Points: The product offers a budget-friendly option that imitates wrought iron through its lightweight design.

Chain-Link Fencing

Initial Cost: $5–$20 per linear foot

Maintenance Cost: Low (minimal upkeep required)

Lifespan: 15 to 20 years

Key Points: The product provides economical solutions for practical use yet fails to match the visual attractiveness of wrought iron and other available options.

The different fencing materials each have their own unique strengths and weaknesses which enable property owners to choose the most appropriate fencing material that aligns with their financial resources and personal preferences and their future requirements.

Frequently Asked Questions (FAQ)

What steps must I complete to successfully execute the installation of decorative wrought iron fence panels and associated gate hardware?

The process of installing decorative wrought iron fence panels with their matching gate requires three essential components which include proper planning and correct fence hardware and appropriate installation equipment. The first step requires you to measure and mark post locations before you proceed with post hole digging at the recommended depth and post installation using concrete for weather-resistant strength. The installation process requires attaching panels to posts which uses brackets or screws that manufacturers designed for ornamental fence systems; the powder coated brackets offer protection against corrosion. Homeowners can install small wrought iron garden or patio enclosures through DIY methods but they should use professional installation for their extended fence sections which include heavy gates because it ensures proper edge alignment and effective long-lasting performance.

Do ornamental fence panels receive powder coating treatment which enhances their strength?

The application of powder coated finishes to decorative wrought iron fence panels and ornamental steel fence components enables their durability enhancement and protection against rust. The powder coating process creates a protective layer which enables outdoor metal to fight against weather conditions and UV radiation and everyday damage. The selection of a finish should focus on multi-stage treatments which include both galvanization and powder coat because these offer superior protection compared to untreated aluminum and ornamental steel.

Do decorative wrought iron garden panels provide greater durability than aluminum and chain link fencing materials?

Wrought iron garden panels provide homeowners with a strong outdoor solution which combines heavy-duty durability with traditional design, yet aluminum fences offer benefits because they weigh less and resist rust. The chain link fence system provides cost-effective and high-quality protection for security purposes but it does not offer visually appealing features. Steel ornamental fence panels with premium powder coated finishes provide an ideal combination of strength and decorative design while aluminum serves as a maintenance-free option when you require protection against corrosion.

Which components do I need to build a decorative ornamental fence panel system?

The basic elements of fence hardware consist of posts and rails and brackets and hinges and gate latch sets and post caps. The structural system of the fence depends on both rails and their connectors which establish connections between posts while decorative rails remain compatible with the design of the panel. The complete ornamental fence system including gates needs heavy-duty hardware which consists of galvanized steel and powder coated metal materials to ensure outdoor durability. The hardware selection must match your panel weight requirements while operating with your selected edge design elements and decorative accessories.

What benefits do decorative wrought iron fence panels bring to outdoor spaces?

Decorative wrought iron fence panels enhance outdoor spaces by their capacity to create architectural features which maintain a classic design. The outdoor living areas are framed by their elaborate scrollwork and finials which function as design elements and barriers. The outdoor decor scheme can be made consistent through panel coordination with gate designs and lighting and plantings which produce a flexible design that matches both contemporary and traditional landscape styles.

What steps do I need to take to maintain ornamental steel and wrought iron fence panels in good condition?

Routine maintenance includes inspecting for rust or chipped powder coat, cleaning dirt and debris, and touching up exposed metal with rust-inhibiting paint or touch-up powder coat products. The fence system maintenance requires annual lubrication of hardware and gate hinges while maintaining the stabilization of posts which should be located at turf edge or pavement edge to maintain their position. The fence system achieves better weather resistance through proper maintenance which increases its lifespan compared to systems that have been neglected and systems that use uncoated chain link which will rust at an accelerated rate.

Do decorative wrought iron fence panels provide solutions for various fencing requirements which include security needs and pet containment and ornamental purposes?

The decorative wrought iron fence panels have flexible design options which allow them to function as security fences and pet containment solutions and decorative fence elements. The combination of taller panels and secure gates which use durable fence hardware components creates an effective security system while the standard height and closely spaced rails provide a reliable solution for pet containment. The decorative purpose requires lower panels which can create border definitions without restricting visibility. Panels can also be combined with masonry or gates to create tailored solutions for different property edges and requirements.

What process do I need to follow to select between aluminum and ornamental steel and wrought iron panels for my project work?

You need to evaluate your project through four essential factors which include budget considerations and the design objectives and maintenance capabilities and required strength for your project. Aluminum offers three advantages which include being lightweight and rust-resistant and needing less maintenance yet it does not provide the same level of durability as wrought iron and ornamental steel. Wrought iron garden panels provide permanent strength through their classic design yet they need protective coating and maintenance work. The ornamental steel fence panels deliver enhanced strength compared to aluminum yet they come with powder coated finishes that grant durability through their protective coating. Your final decision depends on your assessment of climate requirements for coastal salt air and heavy rain and the gate and fence hardware you plan to utilize.

Recently Posted

-

Iron Garden Fence: A Decorative and Durable Solution for Your Garden

January 30, 2026Homeowners select appropriate fencing for their gardens to create beautiful, secure outdoor spaces. An iron garden fence serves du Read More

Read More -

Outdoor Sport Court Fencing: A Comprehensive Guide to Court Containment

January 28, 2026The correct fencing solution provides essential support for building a secure and operational outdoor sports space which meets pro Read More

Read More -

Outdoor Basketball Court Fencing: Choosing the Right Fence for Your Court

January 28, 2026People who want to create their perfect outdoor basketball court often overlook the fencing, which is a vital element of their des Read More

Read More -

Basketball Court with Fence: Enhancing Safety and Playability

January 26, 2026The design elements and court dimensions determine which basketball experience will result in the best outcome. The implementation Read More

Read More